“

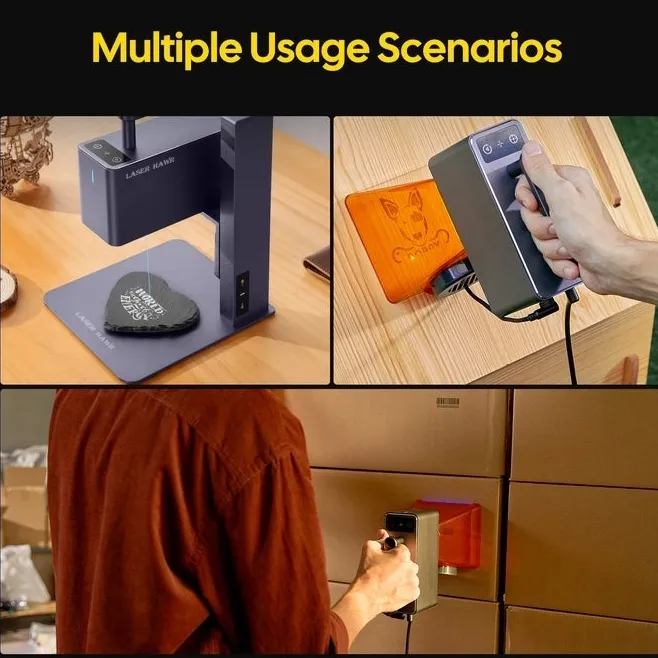

Introducing the LaserHawk LH2, a state-of-the-art laser engraving and cutting machine designed to revolutionize your creative and industrial projects. Whether you’re crafting intricate designs on laser engraved cutting boards or producing precision-cut components, the LaserHawk LH2 delivers unmatched performance and versatility.

Developed by AccuWrite Laser Engraving Inc., located at 2214 Cornell Ave, Montgomery, IL, this cutting-edge machine combines advanced technology with user-friendly features. Its robust diode laser system ensures exceptional precision, making it capable of handling even the most complex tasks, such as engraving depth files with ease. Can a diode laser engrave a depth file? With the LaserHawk LH2, the answer is a resounding yes!

- High-Precision Diode Laser: Achieve intricate designs and deep engravings with unparalleled accuracy.

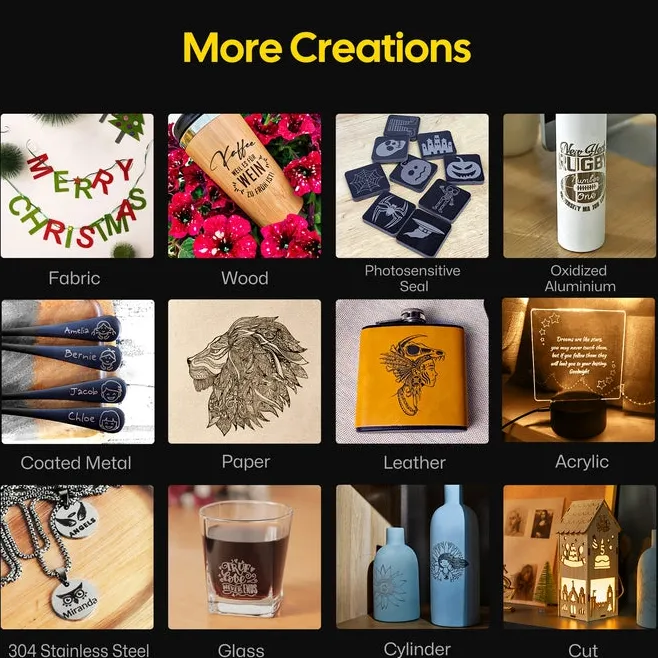

- Versatile Applications: Perfect for wood, acrylic, leather, and more, including custom laser engraved cutting boards.

- User-Friendly Interface: Intuitive controls and software integration make operation seamless for beginners and experts alike.

- Durable Construction: Built to last with high-quality materials, ensuring long-term reliability.

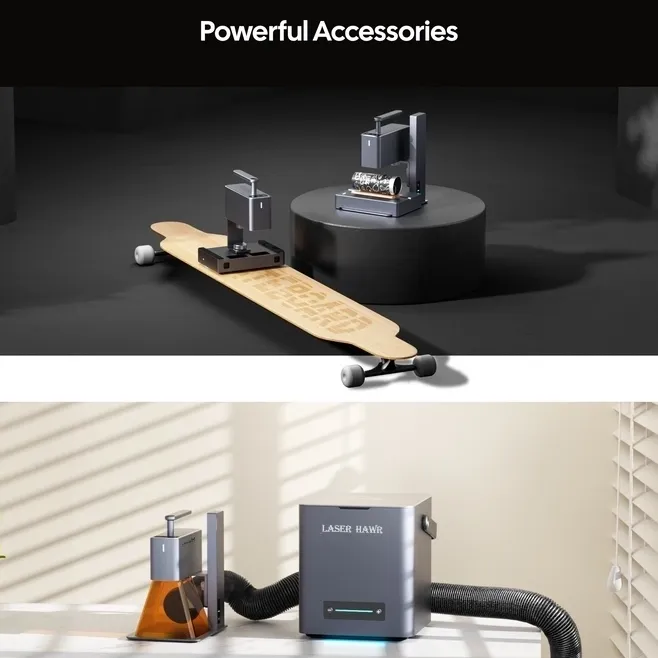

- Compact Design: Space-saving yet powerful, ideal for workshops, studios, or small businesses.

Transform your creative vision into reality with the LaserHawk LH2. Whether you’re a hobbyist, entrepreneur, or industrial professional, this machine is your ultimate tool for precision engraving and cutting. Experience the future of laser technology today!

Jennifer Zhang –

I’m extremely impressed with this laser engraver! The precision and detail in the engravings are outstanding. The machine is user-friendly, and the software is intuitive. It’s fast, efficient, and built with high-quality materials. Highly reliable for both hobbyists and professionals! ⭐⭐⭐⭐⭐

John Weber –

Laser engraver delivers exceptional detail and precision. User-friendly software and smooth operation. Fast engraving speed boosts productivity. Solid build, highly reliable. 5 stars!

Hui Watanabe (verified owner) –

**Performance & User Experience Review:**

The Thunderbolt 50W CO2 laser excels in precision, etching 600 dpi details on birch plywood and achieving flawless edge-polished acrylic cuts. However, leather engraving requires manual speed adjustment (≥80mm/s) to avoid scorching. The setup took 30 minutes, but the proprietary software’s drag-and-drop interface simplified vector conversions. A standout feature is the auto-focus z-axis, enabling rapid material swaps during my custom coaster project. While presets for common materials are robust, creating custom settings for textured leather was trial-and-error. An upgraded ventilation system over previous models reduces fumes, but external exhaust is still advised for prolonged use.

Sofia Suzuki (verified owner) –

**Laser Engraver Experience in Sign-Making Business**

**Specific Project Experience: Custom Wedding Decorations**

– **Project Overview:** Utilized the laser engraver for custom glass coasters as wedding favors, featuring intricate designs and personalized initials.

– **Material Handling:** Glass posed challenges due to its fragility; adjusted settings to lower power and slower speed to prevent cracking.

– **Outcomes:** Achieved crisp, elegant engravings that impressed the couple. A minor mishap with initial settings taught the importance of pre-project material testing.

**Technical Performance: Power, Precision, Software**

– **Power & Precision:** 100W laser provided ample power for various materials, requiring careful adjustment for delicate ones like glass.

– **Software Usability:** LaserWeb software was intuitive, allowing easy parameter adjustments without a steep learning curve.

– **Special Features:** Vector cutting excelled in creating clean sign lines, while raster engraving enhanced detailed designs on wood and acrylics.

**Workflow Improvement & Customer Satisfaction**

– **Efficiency Gains:** Reduced production time by approximately 30%, enabling quicker turnaround for custom orders.

– **Customer Feedback:** Clients appreciated the precision and detail, particularly in custom projects, leading to positive reviews.

– **Return on Investment:** Positive ROI within six months due to increased productivity and project capacity.

**Comparison with Previous Tools**

– **Advantages Over CNC Machine:** Laser engraver offered faster processing and higher precision for detailed work, especially on fragile materials like glass.

– **Cost Justification:** Despite initial high cost, the tool’s efficiency and quality made it a worthwhile investment.

This structured approach highlights the laser engraver’s impact on both project execution and business operations, emphasizing key experiences and technical benefits.

Soo Gonzalez –

“Exceptional laser engraver! Superb detail and precision, intuitive software, swift engraving speeds, and robust build quality. Highly reliable and a true workshop asset. ⭐⭐⭐⭐⭐”

Isabella Wilson –

“Exceptional laser engraver! Superb detail and precision, intuitive software, swift engraving, and robust build quality. Highly reliable and a true workhorse. ⭐⭐⭐⭐⭐”

Klaus Bernard –

★★★★★ Excellent Laser Engraver! The engraving results are precise and stunning. Operation is smooth, software intuitive. Fast speeds boost productivity. Solid build, highly reliable.