The Ultimate Guide to Stainless Steel Laser Engravers

Stainless steel laser engravers have become indispensable tools in various industries, offering precision and versatility for creating intricate designs and markings on stainless steel surfaces. Whether you’re in the jewelry industry, manufacturing kitchenware, or producing custom parts, these machines provide a and durable solution for your engraving needs. In this guide, we’ll explore everything you need to know about stainless steel laser engravers, their benefits, applications, and how to choose the right machine for your business.

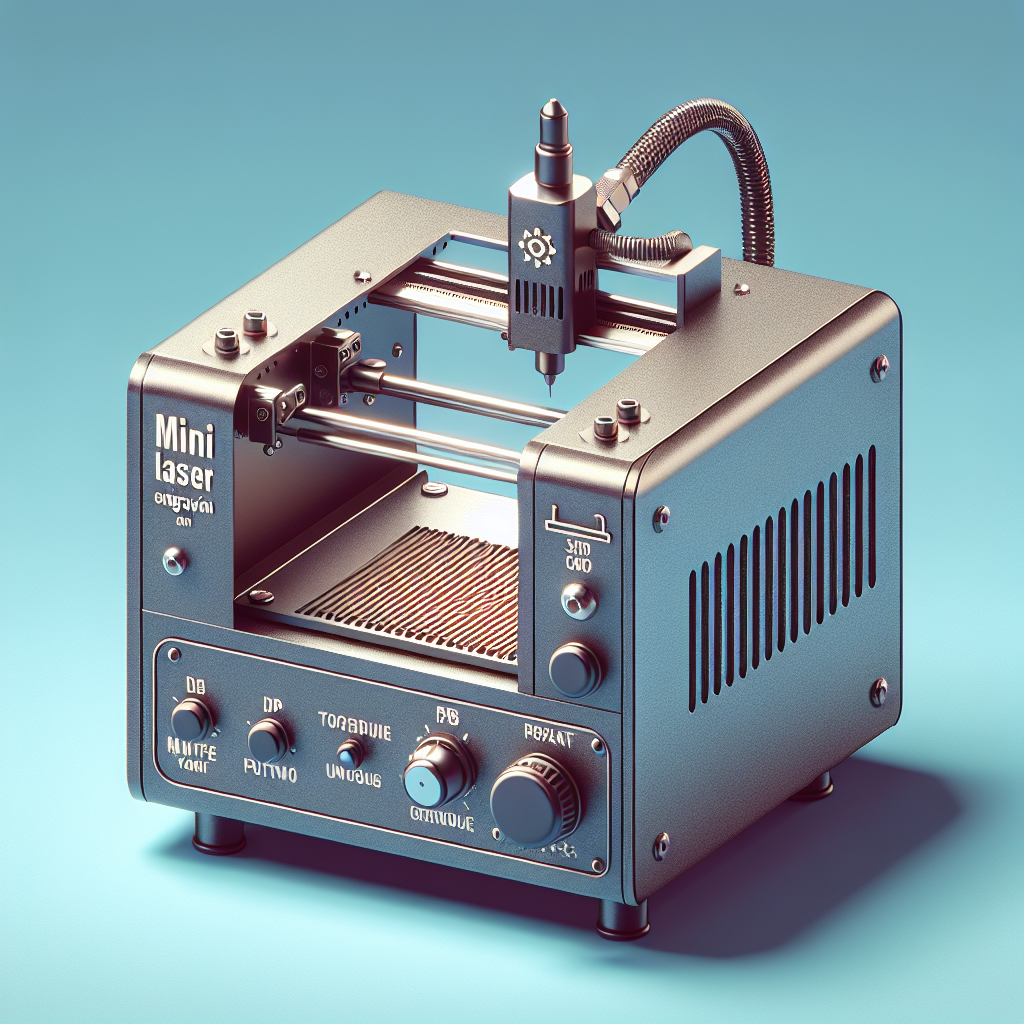

What is a Stainless Steel Laser Engraver?

A stainless steel laser engraver is a specialized machine designed to precise patterns, text, or images onto stainless steel surfaces using a focused laser beam. Unlike traditional engraving methods that use mechanical tools, laser engraving offers non-contact marking, reducing the risk of damaging the material. This makes it ideal for delicate or high-precision projects. The stainless steel laser engraver available on the market combines advanced technology with ease of use, making it accessible to both professionals and hobbyists.

Benefits of Using a Stainless Steel Laser Engraver

There are numerous advantages to using a stainless steel laser engraver, including:

- Precision and Accuracy: The laser beam is highly focused, allowing for intricate details and sharp edges that mechanical tools can’t achieve.

- Durability: Laser engravings are permanent and resistant to wear, ensuring your designs last longer.

- Versatility: Capable of engraving on various materials beyond stainless steel, including metals, plastics, and wood.

- Speed: Faster than traditional methods, reducing production time and increasing efficiency.

- Eco-friendly: Minimal material waste and no harmful chemicals are used in the process.

These benefits make stainless steel laser engravers a preferred choice for industries demanding high-quality and efficient engraving solutions.

Applications of Stainless Steel Laser Engraving

The applications of stainless steel laser engravers are vast and varied:

- Jewelry Making: Creating detailed engravings on bracelets, necklaces, and rings.

- Kitchenware: Personalizing cutlery, cookware, and other stainless steel items with custom designs or logos.

- Automotive Industry: Engraving parts identification numbers or decorative patterns on car components.

- Medical Equipment: Marking surgical instruments and devices with precise information for traceability.

- Custom Signage: Producing high-quality signs and plaques with engraved text and logos.

The versatility of these machines ensures they can adapt to a wide range of projects, from small-scale crafts to large industrial applications.

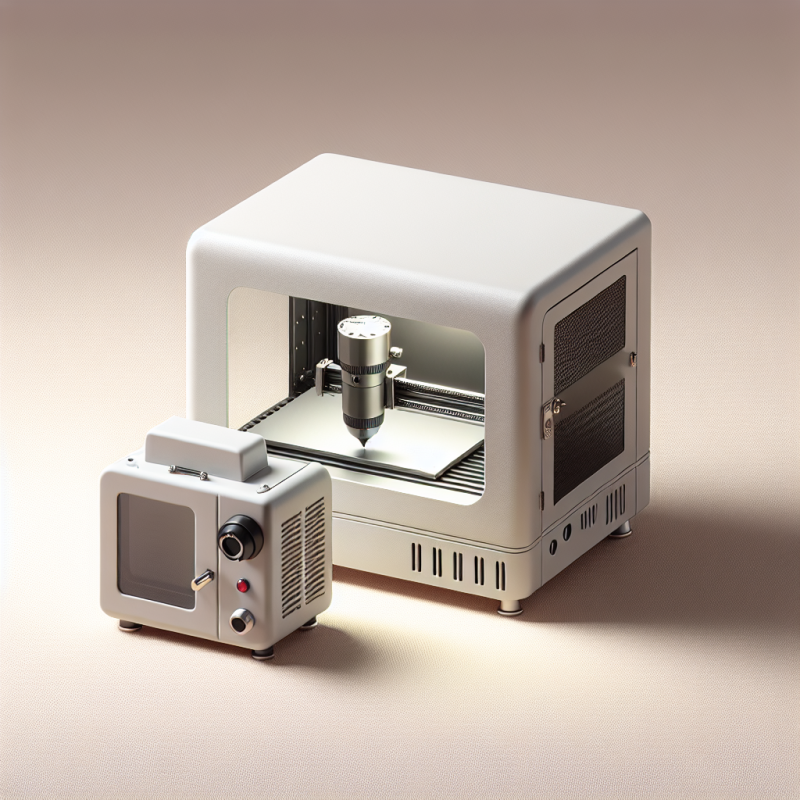

Choosing the Right Stainless Steel Laser Engraver

Selecting the appropriate stainless steel laser engraver involves considering several factors:

- Power (Wattage): Higher wattage is suitable for thicker materials, while lower wattage suffices for thinner ones.

- Material Compatibility: Ensure the machine can handle stainless steel’s high reflectivity and thermal conductivity.

- Design Complexity: Choose a machine capable of handling intricate designs if your projects require detailed work.

- Size Considerations: Decide on the bed size based on the size of your projects.

- Software and Controls: Look for user-friendly software with design tools and easy-to-use controls.

Investing in a high-quality machine ensures durability, performance, and return on investment over time. The stainless steel laser engraver is a top choice for its balance of power, precision, and ease of use.

Maintenance Tips for Your Laser Engraver

To ensure optimal performance and longevity:

- Clean Regularly: Dust and debris can affect accuracy, so clean the machine regularly.

- Inspect Lenses: Check and clean lenses to prevent damage from dust or scratches.

- Ensure Proper Ventilation: Use exhaust systems to remove fumes generated during engraving.

- Safety Gear: Always wear safety goggles and masks when operating the machine.

- Calibration: Regularly calibrate to maintain precise engravings.

Frequently Asked Questions

Q: Can stainless steel laser engravers work on other materials?

Absolutely! While designed for stainless steel, these machines can also engrave on metals, plastics, and wood with appropriate settings.

Q: How much do they cost?

Prices vary widely based on power, size, and features. It’s essential to invest in a machine that meets your project needs without overspending.

Q: Can I customize designs?

Yes! Most machines come with software allowing you to create or import custom designs for unique engravings.

Q: What are best practices for engraving stainless steel?

Ensure the material is clean, use the correct focal length, and choose appropriate laser settings based on thickness and desired depth.

Conclusion

A stainless steel laser engraver is a powerful tool that can elevate your projects with precision and efficiency. Whether you’re in manufacturing or crafting custom items, the benefits of laser engraving are clear. For those ready to enhance their capabilities, consider purchasing the stainless steel laser engraver. This machine offers the performance and quality needed for your most demanding projects.

Embrace the future of engraving with a stainless steel laser engraver today!