The Ultimate Guide to Laser Metal Cutters

Laser metal cutters are revolutionizing the manufacturing and fabrication industries, offering precision, speed, and versatility unlike traditional cutting methods. If you’re considering upgrading your workshop or starting a new project that requires intricate designs and clean cuts, understanding how laser metal cutters work and their benefits is essential. In this article, we’ll explore everything you need to know about technology, including its applications, advantages, and how it can transform your projects.

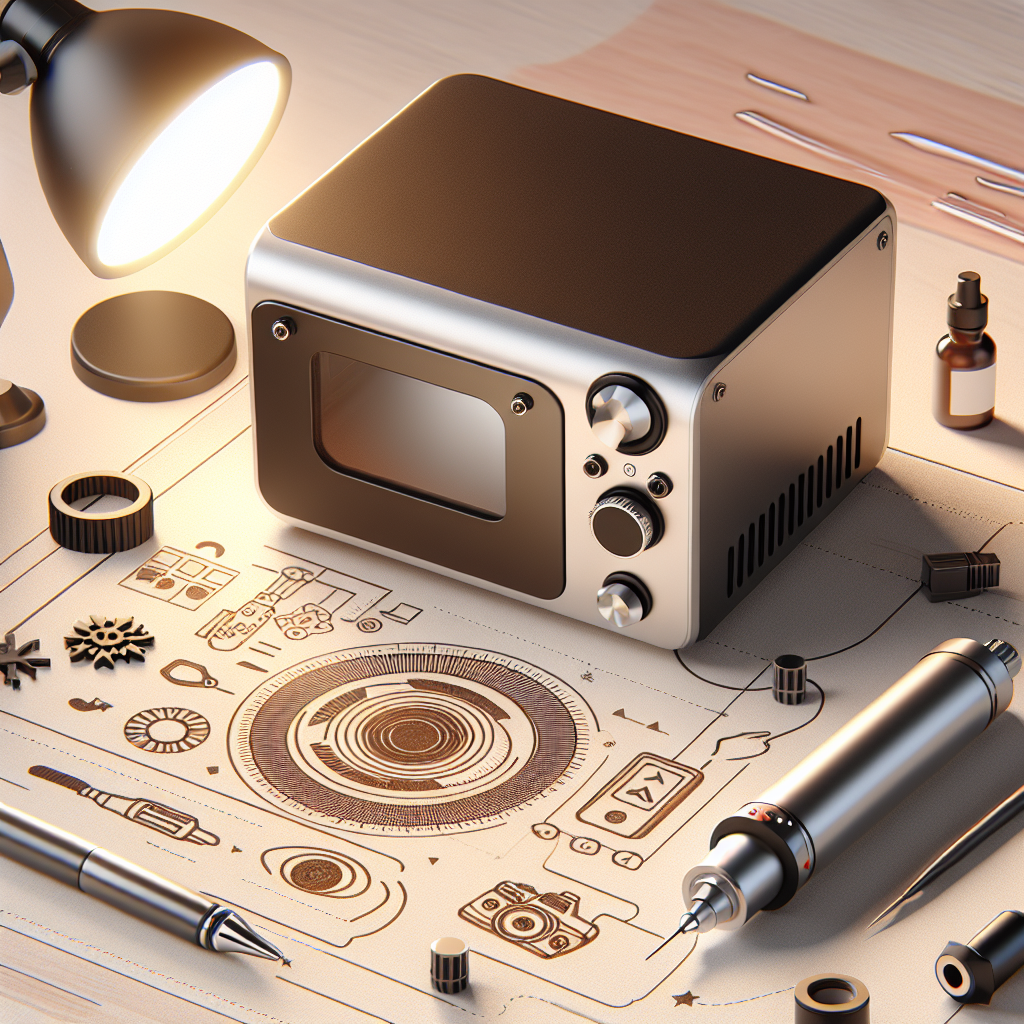

What Is a Laser Metal Cutter?

A laser metal cutter is a machine that uses a focused laser beam to cut through various materials, including metals. The process involves directing high-powered lasers at the material, which vaporizes or melts the metal along the desired cutting path. This method is highly precise and efficient, making it ideal for industries such as automotive, aerospace, jewelry, and more.

The works by focusing a laser beam through a lens or mirror system to create an intense heat source. This concentrated energy melts or vaporizes the material, leaving behind a clean and accurate cut. Unlike traditional cutting methods, which often require physical contact with the material, laser cutting minimizes wear and tear on tools while delivering superior results.

Key Features of Laser Metal Cutters

Laser metal cutters come equipped with advanced features that make them indispensable in modern manufacturing. Here are some key attributes to look for:

- Precision Cutting: Lasers can achieve exceptional accuracy, often within microns, ensuring intricate designs and complex shapes are executed flawlessly.

- Fully Automated Systems: Many laser cutters, like the , come with automated controls that streamline workflows and reduce manual intervention.

- Multipurpose Capabilities: These machines can handle a variety of materials, including steel, stainless steel, aluminum, and even non-metals like acrylic or wood.

- High-Speed Processing: Laser cutting is significantly faster than traditional methods, making it ideal for large-scale production.

Advantages of Using a Laser Metal Cutter

Switching to a laser metal cutter offers numerous benefits that can enhance your productivity and output quality. Some of the most notable advantages include:

- Improved Precision: The ability to make exact cuts reduces material waste and ensures consistent quality in each piece.

- Clean Edges: Laser cutting eliminates the need for secondary finishing processes, as the cuts are smooth and free of burrs or imperfections.

- Versatility: These machines can handle both simple and complex designs, making them suitable for a wide range of industries and applications.

- Cost-Effective: While the initial investment may seem high, the long-term savings from reduced material waste and faster processing make laser cutters a worthwhile purchase.

Question: Are you tired of dealing with messy cuts and wasted materials? A laser metal cutter could be the solution to your problems!

Applications of Laser Metal Cutters

Laser metal cutters are incredibly versatile and can be used in various industries. Here are some common applications:

- Automotive Industry: Cutting precision parts, components, and decorative elements for vehicles.

- Jewelry Making: Engraving and cutting intricate designs into metals like gold and silver.

- Aerospace: Creating lightweight, high-precision parts that meet strict industry standards.

- Furniture Manufacturing: Cutting metal components for chairs, tables, and decorative items.

Maintenance and Safety Considerations

While laser metal cutters are highly efficient, proper maintenance and safety protocols are essential to ensure optimal performance and longevity. Here are some tips to keep in mind:

- Regular Cleaning: Dust and debris can accumulate inside the machine, so it’s important to clean it regularly to maintain efficiency.

- Lens Care: The focusing lens is a critical component of the laser system. Ensure it’s free from scratches and dirt to prevent reduced performance.

- Safety Gear: Always wear appropriate safety gear, including goggles and gloves, when operating or servicing the machine.

Question: Are you familiar with the proper maintenance routines for your laser metal cutter? Regular upkeep can significantly extend its lifespan!

Frequently Asked Questions About Laser Metal Cutters

If you’re new to laser cutting technology, here are answers to some common questions:

- How much does a laser metal cutter cost? The price varies depending on the model and specifications. Entry-level machines can start at around $10,000, while high-end industrial models may cost upwards of $100,000.

- What materials can I cut with a laser metal cutter? Most metals, including steel, aluminum, and stainless steel, as well as non-metals like wood and acrylic, can be processed using laser cutting technology.

- Is laser cutting environmentally friendly? Yes! Laser cutting reduces material waste and eliminates the need for harmful chemicals used in traditional methods, making it a greener option.

Conclusion

A laser metal cutter is an invaluable tool for anyone looking to enhance their manufacturing or crafting capabilities. With its precision, versatility, and efficiency, this technology can revolutionize the way you approach projects. Whether you’re working in a small workshop or running a large-scale production facility, investing in a high-quality laser cutter like the is sure to yield impressive results and long-term benefits.

Question: Have you considered upgrading your equipment with a laser metal cutter? The investment could pay off in improved productivity and quality!