The Ultimate Guide to Laser Foam Cutters: Precision, Efficiency, and Creativity in One Tool

Are you looking for a versatile and efficient tool that can revolutionize your crafting, prototyping, or industrial projects? Look no further than the laser foam cutter. This innovative device combines precision, speed, and versatility, making it an indispensable tool for professionals and hobbyists alike. In this comprehensive guide, we’ll explore everything you need to know about laser foam cutters, their applications, benefits, and how they can transform your work. Let’s dive in!

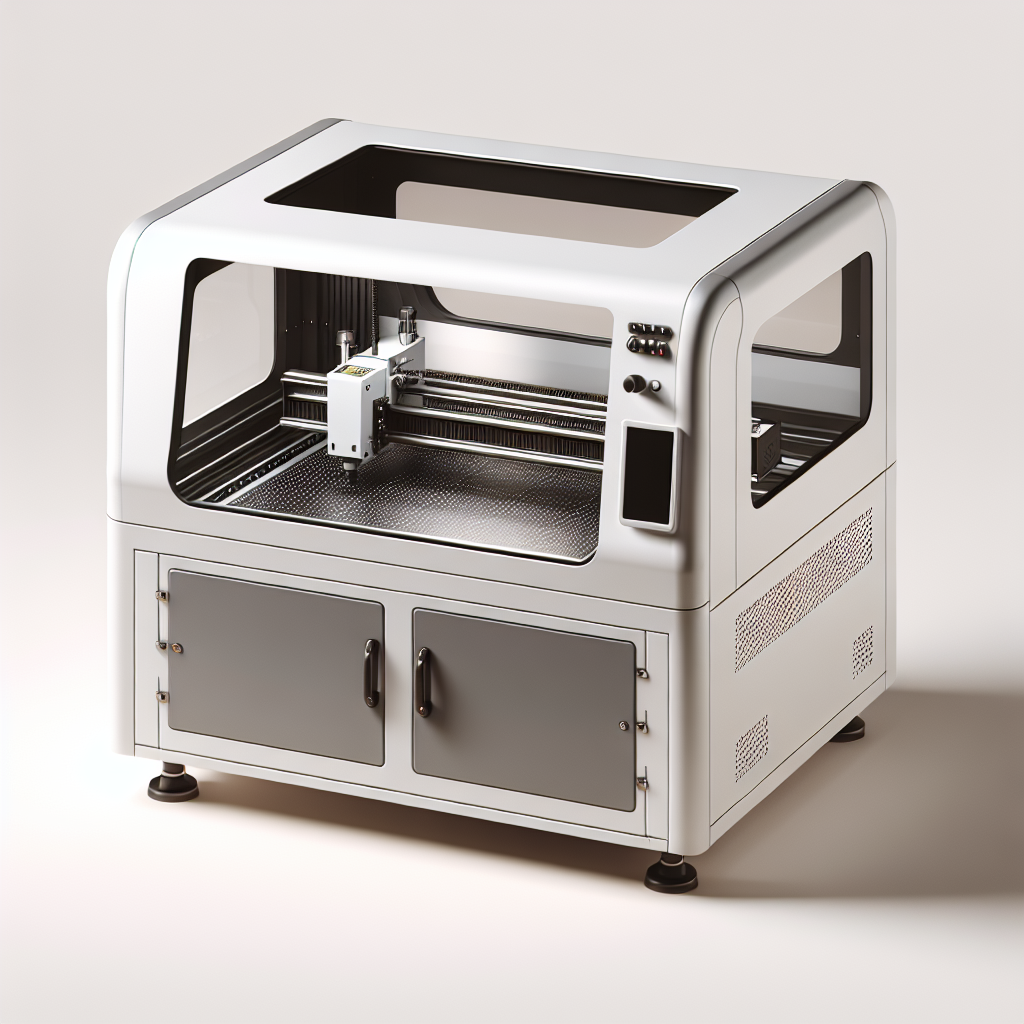

What is a Laser Foam Cutter?

A laser foam cutter is a machine designed to precisely cut and engrave various materials using a high-powered laser beam. While it’s commonly associated with cutting foam, this versatile tool can handle a wide range of materials, including wood, metal, plastic, leather, and more. The laser beam heats the material and vaporizes it, creating clean, precise cuts without leaving behind any rough edges or residue.

One of the standout features of a laser foam cutter is its ability to work with computer-aided design (CAD) software. This allows users to create intricate designs and patterns that are then transferred directly to the material. Whether you’re creating custom signage, prototypes, or decorative items, this tool offers unparalleled precision and creativity.

Key Benefits of Using a Laser Foam Cutter

Before diving into how a laser foam cutter works, let’s highlight some of its key benefits:

- Precision Cutting: The laser beam ensures clean, accurate cuts with minimal material waste.

- Versatility: Capable of cutting and engraving a wide range of materials, making it suitable for multiple industries.

- Speed: Quickly processes materials, reducing production time and increasing efficiency.

- Ease of Use: User-friendly interface with CAD software integration simplifies the design and cutting process.

- Cost-Effective: Reduces material waste and minimizes labor costs compared to traditional cutting methods.

These benefits make a laser foam cutter an excellent investment for businesses and individuals looking to streamline their production processes or explore creative projects.

How Does a Laser Foam Cutter Work?

To understand the full potential of a laser foam cutter, it’s essential to know how it operates. The machine uses a laser beam, which is focused through a lens to create an intense beam of light capable of melting or vaporizing the material being cut. Here’s a step-by-step breakdown:

- Design Creation: Users create a design using CAD software or import pre-existing files.

- Laser Alignment: The laser beam is aligned with the material, ensuring accurate cutting paths.

- Cutting/Engraving: The laser beam heats and melts/vaporizes the material along the programmed path.

- Cooling: Some systems use cooling mechanisms to prevent overheating or warping of materials.

This process allows for extremely precise cuts, even in complex designs. The result is a clean, professional finish that traditional cutting methods often struggle to achieve.

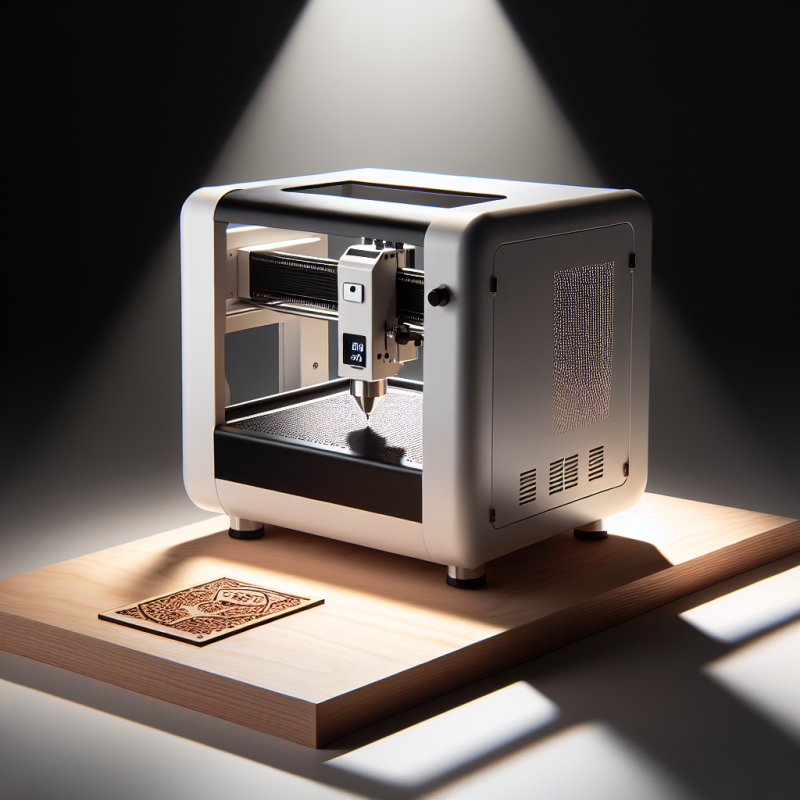

Applications of Laser Foam Cutters

The versatility of a laser foam cutter makes it suitable for numerous applications across different industries. Here are some of the most common uses:

- Crafting and Art: Create intricate designs, patterns, and decorative items from various materials.

- Prototyping: Rapidly produce prototypes for products in manufacturing or design industries.

- Signage Production: Engrave or cut letters and logos into materials like wood, plastic, or metal.

- Fabrication: Cut precise shapes and components for machinery, furniture, or construction projects.

- Customization: Personalize items like jewelry, name tags, or gift boxes with custom engravings.

The possibilities are endless! Whether you’re working on a small-scale project or large-scale production, a laser foam cutter can adapt to your needs.

Choosing the Right Laser Foam Cutter

With so many options available in the market, selecting the right laser foam cutter can be overwhelming. Here are some factors to consider:

- Laser Power: Higher power lasers are better for thicker or harder materials but may require more safety precautions.

- Cutting Area: Choose a machine with a cutting area that matches your project needs, whether small-scale or industrial.

- Material Compatibility: Ensure the laser cutter is compatible with the materials you plan to work with (e.g., foam, wood, metal).

- User Interface: Look for an intuitive interface and CAD software integration for ease of use.

By evaluating these factors, you can select a laser foam cutter that perfectly aligns with your requirements and budget. For more information on specific models, check out our .

Maintenance and Safety Tips

To ensure optimal performance and longevity of your laser foam cutter, proper maintenance and safety practices are essential. Here are some tips:

- Clean Regularly: Dust and debris can accumulate inside the machine, affecting its performance. Clean it regularly as per the manufacturer’s instructions.

- Inspect Lasers: Check the laser optics for any damage or wear and replace them if necessary.

- Maintain Cooling Systems: Ensure cooling mechanisms are functioning properly to prevent overheating.

- Follow Safety Guidelines: Always wear protective eyewear, operate the machine in a well-ventilated area, and keep flammable materials away from the workspace.

By following these maintenance and safety tips, you can maximize the lifespan of your laser foam cutter while ensuring safe operation.

Frequently Asked Questions

Before we wrap up, let’s address some common questions about laser foam cutters:

- Is a laser foam cutter suitable for home use? Yes! Many models are compact and user-friendly, making them ideal for home projects.

- Can it cut metal? Yes, some laser foam cutters are capable of cutting and engraving metal, though higher power lasers may be needed for thicker materials.

- How expensive is a laser foam cutter? Prices vary widely depending on the model, size, and features. Basic models start around $500, while industrial-grade machines can cost thousands of dollars.

If you’re still unsure about whether a laser foam cutter is right for your needs, consider reaching out to manufacturers or reading reviews from other users.

Conclusion

A laser foam cutter is an incredibly versatile and efficient tool that can elevate your projects to new heights. Its ability to precisely cut and engrave a wide range of materials makes it a valuable asset for both professionals and hobbyists. Whether you’re creating intricate designs, prototyping products, or producing custom signage, this machine offers unmatched precision and creativity.

If you’re ready to take your crafting or manufacturing projects to the next level, investing in a laser foam cutter is an excellent decision. With proper maintenance and safety practices, it can serve as a reliable tool for years to come. Happy cutting!