The Ultimate Guide to Laser Cutters for MDF

Laser cutters have revolutionized the way we work with materials like **MDF** (Medium Density Fiberboard). These precision tools offer unparalleled accuracy and efficiency, making them indispensable in woodworking, crafting, and industrial applications. If you’re considering investing in a laser cutter for MDF, this guide will walk you through everything you need to know about their features, benefits, and how to choose the right one for your needs. Plus, we’ll address common questions and provide tips for getting the most out of your machine.

##

What is a Laser Cutter?

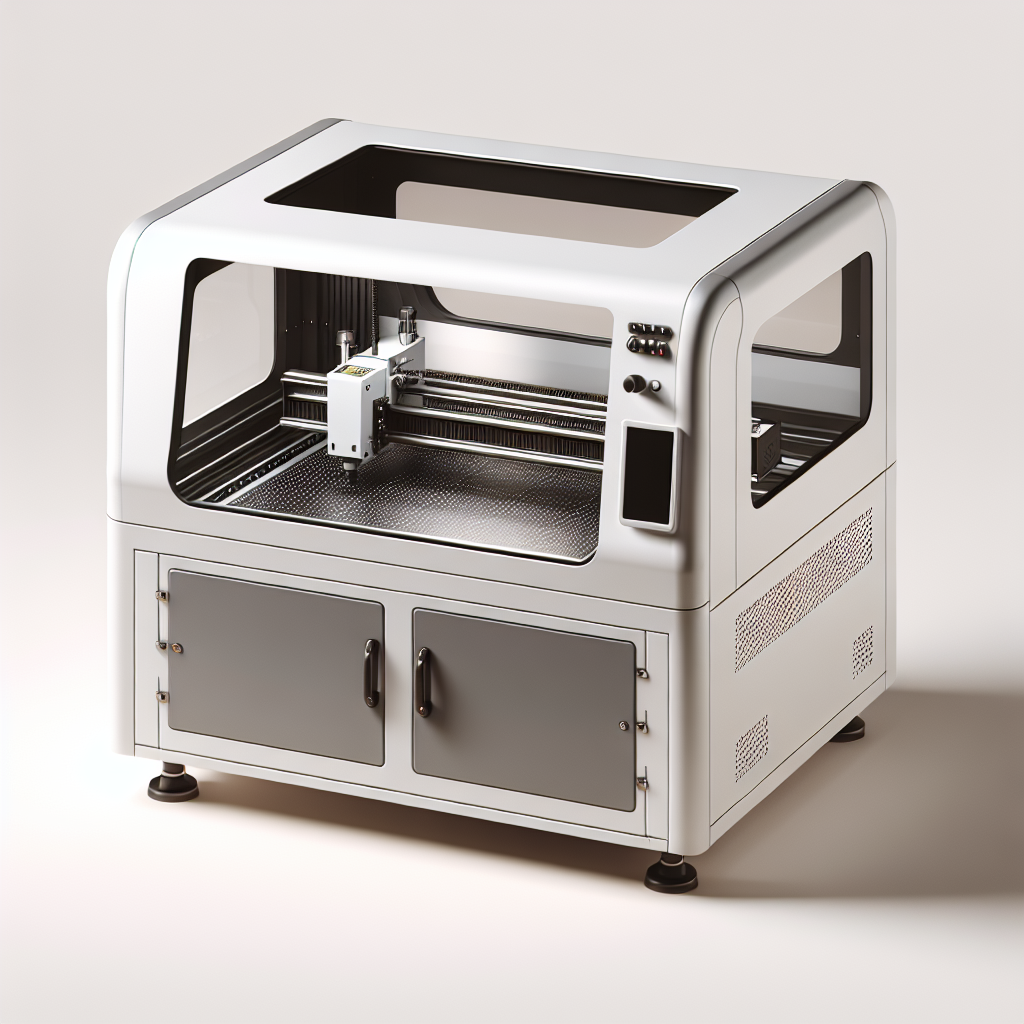

A laser cutter is a machine that uses a focused beam of light (laser) to cut, engrave, or etch materials. Unlike traditional cutting methods, laser cutters operate with extreme precision and speed, making them ideal for intricate designs and large-scale projects alike. The is specifically designed to handle the unique properties of this material, ensuring clean cuts and precise engravings every time.

Laser cutters work by directing a high-powered laser beam through optics that focus the light onto the surface of the material. The intense heat generated by the laser melts or vaporizes the material, creating smooth edges and detailed patterns. This process is not only faster than manual cutting but also produces consistently high-quality results, making it a favorite among craftsmen, hobbyists, and industrial manufacturers.

##

Why Choose a Laser Cutter for MDF?

MDF is a popular material in woodworking due to its density, strength, and smooth surface finish. However, cutting and engraving MDF with traditional tools can be time-consuming and labor-intensive. This is where laser cutters shine:

- Precision Cutting: Laser cutters deliver razor-sharp cuts with minimal material waste, ensuring your designs are executed flawlessly.

- Speed: Compared to manual cutting methods, laser cutters significantly reduce the time required for complex projects.

- Durability: The focused laser beam ensures that even intricate details remain intact, making it ideal for decorative and functional pieces alike.

Additionally, laser cutters can handle a variety of materials beyond MDF, including wood, acrylic, leather, and more. This versatility makes them a valuable addition to any workshop or manufacturing facility.

##

How to Choose the Right Laser Cutter for Your Needs

With so many laser cutters available on the market, selecting the right one can be overwhelming. Here are some key factors to consider when choosing a laser cutter for MDF:

- Laser Power: Higher power lasers are better suited for thicker materials and faster cutting speeds. Ensure the machine you choose has enough power to handle your project requirements.

- Cutting Area: Consider the size of the projects you plan to work on. Larger cutting areas allow for bigger designs, but smaller machines can still be highly effective for detailed work.

- Software Compatibility: Check if the machine supports popular design software like Adobe Illustrator or CorelDRAW. Compatibility is crucial for seamless workflow integration.

If you’re looking for a reliable and versatile option, the laser cutter for MDF stands out as an excellent choice. Its compact design, powerful laser, and user-friendly interface make it ideal for both beginners and experienced users.

##

Applications of Laser Cutters in Woodworking

Laser cutters are incredibly versatile tools with a wide range of applications in woodworking. Whether you’re crafting decorative items, furniture, or functional pieces, here are some common uses:

- Cutting Complex Shapes: Laser cutters can handle intricate designs and curved patterns that would be difficult to achieve manually.

- Engraving: Create detailed textures, logos, or artwork on the surface of MDF with precision and ease.

- Fabrication: Use laser cutters for producing custom parts, joints, and components in furniture-making and cabinetry.

The ability to combine cutting and engraving in one machine makes laser cutters a must-have tool for any woodworking project. Their adaptability ensures that you can tackle a variety of tasks with minimal setup time.

##

Tips for Using Your Laser Cutter

To get the most out of your laser cutter, here are some tips and best practices:

- Material Preparation: Ensure your MDF is clean and free from dust or debris before cutting. This helps maintain the quality of your cuts and extends the life of your machine.

- Fine-Tuning Settings: Experiment with different laser settings to achieve the desired cut depth and finish. Start with lower power settings and gradually increase as needed.

- Maintenance: Regularly clean the optics and ensure all parts are well-lubricated to prevent dust buildup and mechanical wear.

By following these simple guidelines, you can maximize the performance of your laser cutter and produce high-quality results consistently.

##

Frequently Asked Questions

Q: Can a laser cutter cut through multiple layers of MDF at once?

A: Yes, depending on the thickness and power of the laser. Thicker materials may require slower cutting speeds or multiple passes to achieve clean cuts.

Q: Is it safe to use a laser cutter in a home workshop?

A: Absolutely! Modern laser cutters are designed with safety features like enclosed chambers, emergency stop buttons, and ventilation systems. Always follow the manufacturer’s guidelines to ensure safe operation.

Q: How much does it cost to run a laser cutter?

A: The operating costs of a laser cutter are relatively low compared to traditional cutting methods. Electricity usage is minimal, and the machine requires little maintenance over its lifespan.

##

Conclusion

If you’re looking for a tool that combines precision, speed, and versatility, a laser cutter for MDF is an excellent investment. Whether you’re a hobbyist, artisan, or industrial manufacturer, these machines can elevate your woodworking projects to new heights. With the right machine, like the laser cutter for MDF, you’ll be able to create intricate designs and durable products with ease.

So, what are you waiting for? Dive into the world of laser cutting and unlock your creative potential today!