The Ultimate Guide to Laser Cutter Lasers: Revolutionizing Precision Cutting

Welcome to an in-depth exploration of laser cutter lasers, a groundbreaking tool transforming industries with its precision and efficiency. Whether you’re a seasoned professional or a curious newcomer, this guide will walk you through everything you need to know about . Let’s dive in!

## Introduction

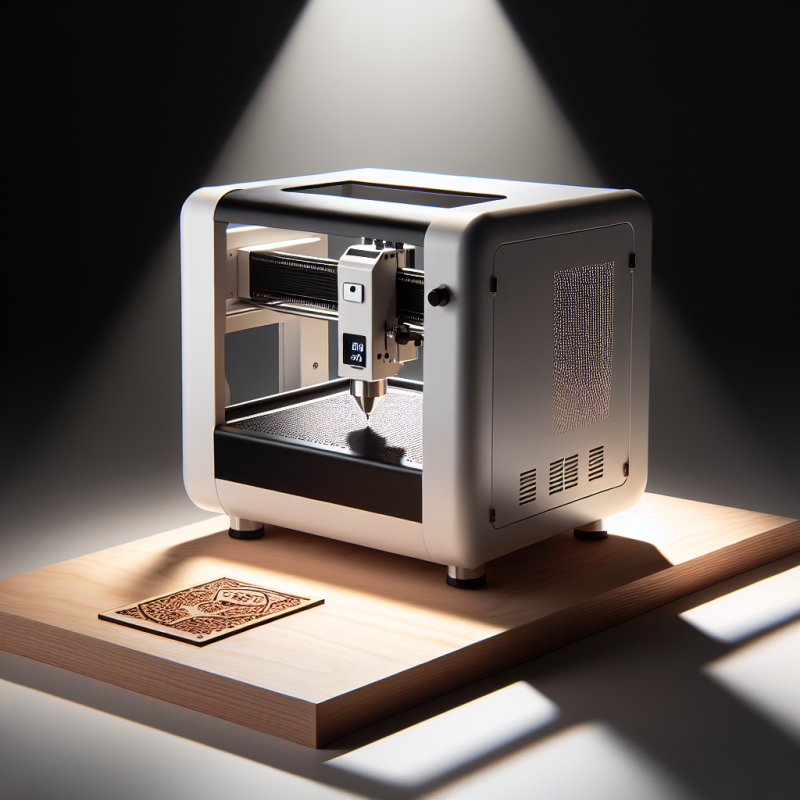

Laser cutter lasers are innovative tools that use focused light beams to cut and engrave materials with unparalleled accuracy. This technology is reshaping industries from manufacturing to art, offering a versatile solution for diverse applications. But how does it work? What benefits does it bring? Read on to find out.

## Benefits of Using a Laser Cutter Laser

Why should you choose a laser cutter laser over traditional methods?

- Precision: Achieve intricate designs with unmatched accuracy, ideal for delicate materials like leather.

- Speed: Cut through various materials quickly, enhancing productivity and efficiency.

- Versatility: Suitable for cutting, engraving, and marking across industries.

These benefits make laser cutter lasers indispensable in modern workflows. They are a must-have for anyone seeking precision and speed in their projects.

## Applications Across Industries

Laser cutter lasers are used in various fields:

- Fashion: Leather engraving for custom designs on bags, belts, and accessories.

- Customization: Personalized items like engraved jewelry or name tags.

- Prototyping: Rapid production of models in product development.

This versatility makes laser cutter lasers a valuable asset across multiple sectors. Whether you’re crafting luxury goods or prototyping new designs, this tool adapts to your needs.

## Choosing the Right Laser Cutter Laser

Selecting the right machine involves considering several factors:

- Material Compatibility: Ensure it handles the materials you work with, such as leather or metal.

- Power Output: Higher wattage may be needed for thicker materials.

- Budget: Balance between cost and features to find the best fit for your needs.

Visit our site to explore options tailored to your projects, ensuring you invest in a machine that offers both quality and value.

## Maintenance Tips

To prolong the life of your laser cutter laser:

- Clean Regularly: Dust can affect performance; keep it clean for optimal operation.

- Replace Parts: Update components as recommended to maintain efficiency.

Proper care ensures your machine remains reliable and effective, providing years of service. Refer to the user manual or our support page for detailed maintenance guidelines.

## Common Questions About Laser Cutter Lasers

How does a laser cutter work?

A laser cutter emits focused light beams that vaporize material at specific points, allowing precise cutting and engraving without physical contact. This method minimizes wear and tear on the tool while achieving high-quality results.

What materials can it cut?

It excels with non-metallic materials like leather, wood, and plastic. While it can handle some metals, its efficiency varies depending on material thickness and type.

## Conclusion

Laser cutter lasers are a transformative tool for any creative or manufacturing endeavor. Their precision, speed, and versatility make them a worthwhile investment for professionals and hobbyists alike. Ready to experience the difference? Explore our collection of high-quality laser cutter lasers at today!

Start your journey into precision craftsmanship with a laser cutter laser—where innovation meets creativity.