The Ultimate Guide to Commercial Laser Engravers: Enhancing Your Woodworking Projects

Are you looking for a tool that can take your woodworking projects to the next level? If precision, creativity, and efficiency are what you’re after, then a **commercial laser engraver** might just be the perfect addition to your workshop. Whether you’re framing wood, creating intricate designs, or adding personalized touches to furniture, this innovative technology offers endless possibilities. In this article, we’ll explore everything you need to know about commercial laser engravers, their benefits, and how they can transform your woodworking projects.

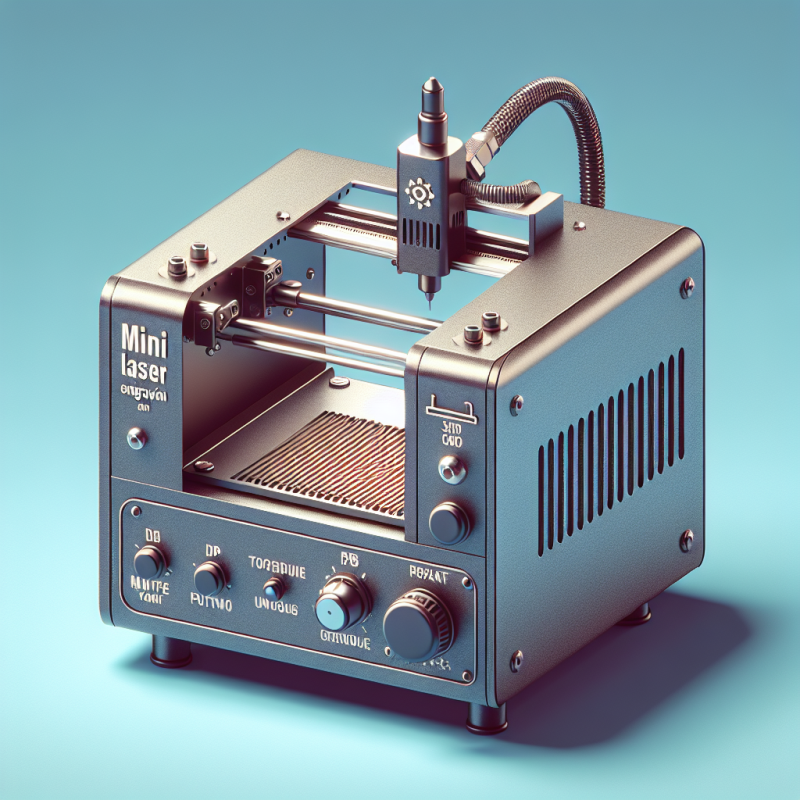

What is a Commercial Laser Engraver?

A **commercial laser engraver** is a machine that uses high-powered lasers to or engrave designs onto various materials, including wood. Unlike traditional engraving methods, which often require manual carving or mechanical tools, laser engravers offer unparalleled precision and speed. They are widely used in woodworking, furniture making, signage creation, and even custom framing projects. If you’re wondering, “How does a laser engraver work?” the process involves directing a focused beam of light onto the material to remove or alter its surface, creating detailed designs with ease.

One of the most popular options in this category is the **** designed for framing and woodwork. This machine combines advanced technology with user-friendly features, making it accessible even for those new to laser engraving.

Benefits of Using a Commercial Laser Engraver

The decision to invest in a **commercial laser engraver** comes with numerous benefits that can significantly enhance your woodworking projects. Here are some key advantages:

- Precision and Accuracy: Lasers allow for extremely precise cuts and engravings, ensuring even the most intricate designs are executed flawlessly.

- Speed: Compared to traditional methods, laser engraving is much faster, saving you time and allowing you to complete projects more efficiently.

- Durability: The engravings created by a commercial laser engraver are permanent and resistant to wear, ensuring your designs last for years.

- Versatility: These machines can work with a variety of materials, including wood, metal, plastic, and glass, making them a versatile tool for any workshop.

For those interested in framing wood or creating custom decorative items, the **** is an excellent choice. Its ability to handle delicate materials with precision makes it ideal for intricate designs.

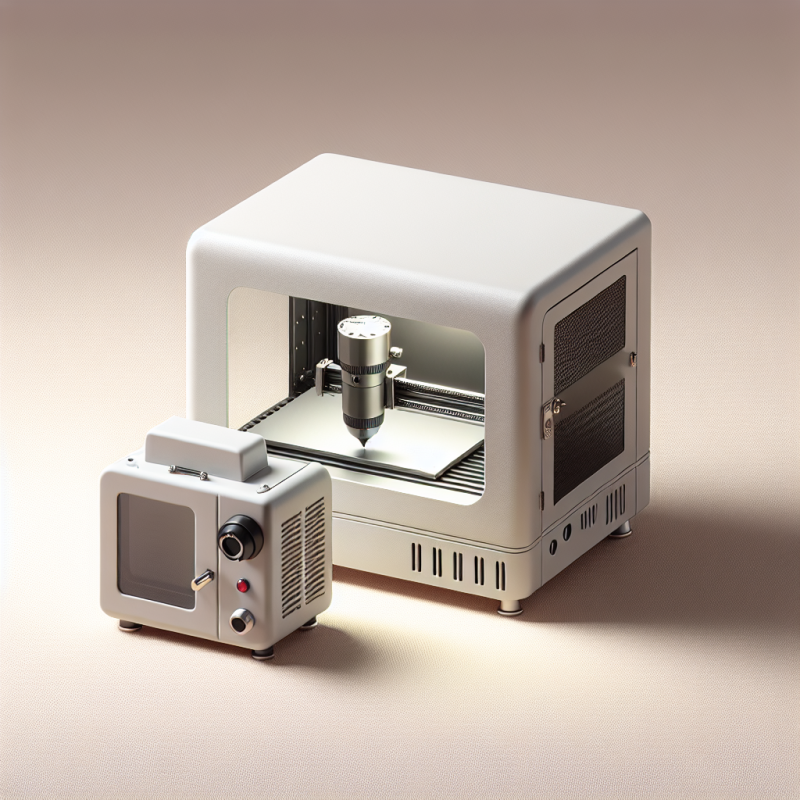

Key Features of a Commercial Laser Engraver

When choosing the right **commercial laser engraver**, it’s important to consider its features and capabilities. Here are some key aspects to look for:

- Laser Power: The power of the laser determines how quickly and deeply it can cut or engrave into materials. Higher power lasers are better suited for thicker or harder materials.

- Speed Settings: Adjustable speed settings allow you to control the precision and quality of your engravings, ensuring optimal results for different projects.

- User-Friendly Interface: A simple and intuitive interface makes it easier to operate the machine, even for those without prior experience.

- Safety Features: Look for machines with built-in safety features, such as emergency stop buttons and laser safety enclosures, to ensure safe operation.

- Connectivity: Many modern laser engravers come with USB or Wi-Fi connectivity, allowing you to transfer designs directly from your computer.

If you’re considering purchasing a **commercial laser engraver**, the **** is designed with these features in mind, making it an excellent investment for your woodworking needs.

How to Choose the Right Commercial Laser Engraver

Selecting the right **commercial laser engraver** depends on your specific needs and the type of projects you plan to undertake. Here are some factors to consider:

- Budget: Determine how much you’re willing to spend, as prices can vary widely depending on the machine’s features and capabilities.

- Material Compatibility: Consider what materials you’ll be working with. Some laser engravers are better suited for wood, while others can handle a wider range of materials.

- Project Size: Think about the size of your projects. Smaller machines may work fine for small-scale projects, but larger ones may be needed for bigger tasks.

- Software Compatibility: Ensure the machine is compatible with the software you’ll be using to design and create your engravings.

If you’re focused on woodwork and framing, the **** is specifically designed for these applications, offering the perfect balance of power and precision.

Tips for Using a Commercial Laser Engraver

Once you have your **commercial laser engraver**, here are some tips to help you get the most out of it:

- Start Small: If you’re new to laser engraving, start with simple designs and small-scale projects to get a feel for the machine.

- Practice on Scrap Material: Before working on your final project, practice your designs on scrap material to ensure the settings are correct.

- Experiment with Different Materials: Don’t be afraid to try out different materials to see what works best with your machine.

- Maintain Your Machine: Regularly clean and maintain your laser engraver to ensure it continues to perform at its best.

By following these tips, you’ll be able to maximize the potential of your **commercial laser engraver** and create stunning woodwork and framing projects.

Conclusion

If you’re looking to elevate your woodworking projects with precision, creativity, and efficiency, a **commercial laser engraver** is an investment worth considering. Whether you’re framing wood, creating intricate designs, or adding personalized touches to furniture, this versatile tool can help you achieve amazing results. For those focused on woodwork and framing, the **** is a top choice that offers the perfect combination of power and precision.

If you’re ready to take your woodworking projects to new heights, it’s time to explore the world of commercial laser engravers and see how they can transform your craft.