The Artistry of Laser Engraving Wood: Precision Meets Creativity

Laser engraving wood has become a popular method for creating intricate designs, patterns, and text on wooden surfaces. This innovative technique combines precision with creativity, allowing artists, craftsmen, and hobbyists to achieve stunning results. If you’re curious about how laser engraving works or how it can elevate your woodworking projects, this article will guide you through the process, benefits, and applications of *laser engrave wood*. Let’s dive in!

What is Laser Engraving?

Laser engraving is a modern manufacturing technique that uses a focused laser beam to etch or cut materials. Unlike traditional engraving methods, which often involve mechanical tools, laser engraving offers unparalleled precision and flexibility. The process involves directing the laser beam at high speeds across the surface of the material, removing layers of wood to create detailed designs.

The key advantage of laser engraving is its ability to work with a wide range of materials, including wood. By adjusting the intensity and speed of the laser, you can control the depth of the engraving, from subtle textures to deep cuts. This makes it an ideal choice for both small-scale projects like custom jewelry boxes and large-scale applications such as decorative panels.

Why is Laser Engraving Wood Popular?

Laser engraving wood has gained popularity due to its versatility, precision, and the professional finish it provides. Here are some reasons why this technique is favored by many:

- Precision: The laser beam can create intricate details with extreme accuracy, making it perfect for complex designs.

- Speed: Compared to traditional engraving methods, laser engraving is much faster, especially for repetitive patterns or large areas.

- Customization: You can easily input custom designs, text, or images into the laser machine, allowing for unlimited creativity.

- Non-Contact Process: Since there is no physical contact between the tool and the material, there’s minimal risk of damage to the wood.

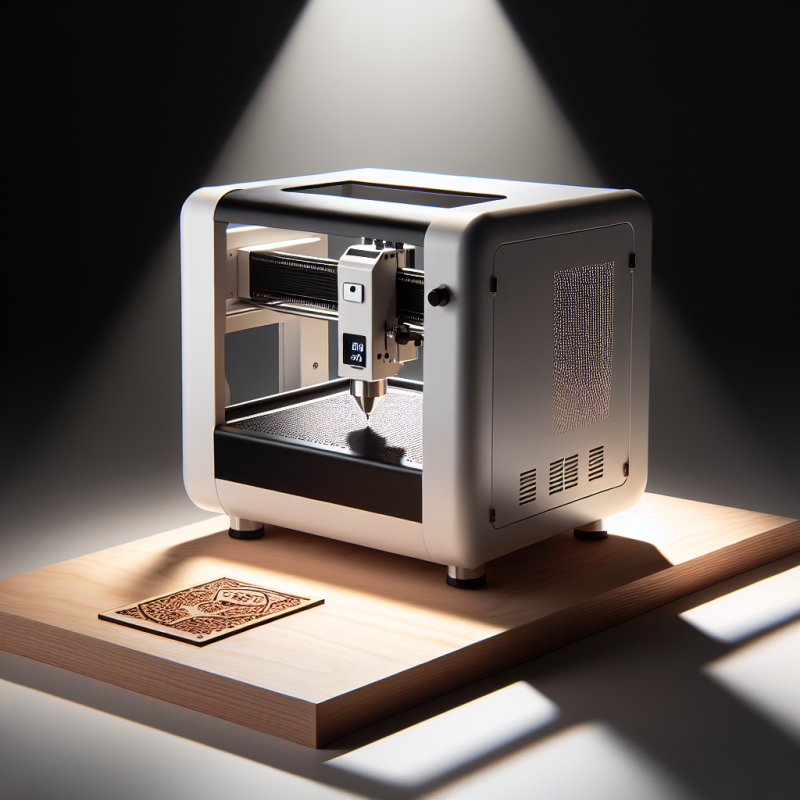

If you’re wondering how to get started with laser engraving, the first step is to invest in a reliable laser cutter or engraver. You can explore options like the laser engrave wood machine, which offers both cutting and engraving capabilities. These machines are user-friendly and come with software that simplifies the design process.

Selecting the Right Wood for Laser Engraving

Not all types of wood are created equal when it comes to laser engraving. The choice of wood can significantly impact the quality of your final product. Here are some factors to consider:

- Hardness: Softer woods like pine or basswood are easier to engrave and produce cleaner results. Harder woods like oak may require more powerful lasers or additional settings adjustments.

- Grain: Open-grained woods like walnut can add texture to your designs, while closed-grained woods like mahogany provide a smoother finish.

- Moisture Content: Ensure the wood is dry before engraving, as moisture can cause warping or uneven results.

Before you begin, it’s also essential to prepare your wood properly. Sanding the surface to remove rough spots and ensuring it’s clean will help achieve a professional-looking finish. Now that you know how to select and prepare your wood, let’s explore some popular techniques for laser engraving.

Laser Engraving Techniques

There are several techniques you can use to create unique effects with laser engraving wood:

- Deep Engraving: This involves cutting deeper into the wood, creating raised or recessed designs. It’s ideal for plaques, signs, and decorative items.

- Surface Engraving: Shallow engravings are perfect for text, fine details, or delicate patterns. They add a subtle yet elegant touch to wooden surfaces.

- Burnishing: By adjusting the laser’s power, you can create a darkened surface without removing material. This technique is great for creating shaded areas in designs.

Experimenting with these techniques can help you achieve a variety of effects. For instance, combining deep and shallow engraving can add depth and dimension to your work. If you’re looking for inspiration, check out the laser engrave wood machine’s capabilities and see how others have used it in their projects.

Applications of Laser Engraving Wood

Laser engraving is a versatile technique with countless applications. Here are some popular uses:

- Furniture: Add custom designs, initials, or patterns to chairs, tables, and other furniture pieces.

- Jewelry Boxes: Create personalized engravings on wooden jewelry boxes for a unique touch.

- Signage: Laser-engraved signs are durable and professional-looking, perfect for businesses or homes.

- Decorative Items: From picture frames to coasters, laser engraving can transform simple items into works of art.

The possibilities are endless! Whether you’re creating a small gift or a large-scale project, laser engraving wood offers unmatched precision and creativity. To bring your ideas to life, consider investing in a high-quality machine like the laser engrave wood cutter, which can handle both small and large projects with ease.

Maintenance and Safety Tips

Like any machinery, laser cutters require proper care to ensure optimal performance and longevity. Here are some maintenance tips:

- Cleanliness: Regularly clean the machine to remove dust or debris that may accumulate during use.

- Lens Care: Keep the laser lenses free from scratches and dirt, as they are crucial for maintaining beam focus.

- Ventilation: Ensure your workspace is well-ventilated to avoid inhaling harmful fumes produced during engraving.

Safety should always come first. Wear protective eyewear and gloves when operating the machine, and make sure to follow all manufacturer guidelines. By taking good care of your equipment and prioritizing safety, you can enjoy years of reliable service from your laser cutter.

Frequently Asked Questions

If you’re new to laser engraving wood, here are answers to some common questions:

- Can I engrave on any type of wood? While most woods can be engraved, softer woods like pine and basswood are recommended for beginners due to their ease of use.

- How detailed can laser engravings be? The level of detail depends on the machine’s specifications. High-resolution machines can produce intricate designs with exceptional clarity.

- Is laser engraving permanent? Yes, once engraved, the design becomes a permanent part of the wood surface, making it ideal for long-lasting projects.

If you have more questions or need assistance choosing the right equipment, don’t hesitate to consult with experts or refer to resources like the laser engrave wood machine’s user manual.

Conclusion

Laser engraving wood is a powerful technique that combines precision, creativity, and versatility. Whether you’re a hobbyist or a professional, investing in a reliable laser cutter can take your woodworking projects to the next level. With the right equipment, techniques, and safety precautions, you can create stunning engravings that showcase your skills and imagination.

If you’re ready to explore the world of laser engraving, consider checking out the laser engrave wood machine. It’s a fantastic tool for both small and large projects, offering flexibility and ease of use. Happy creating!