The Art of Precision: Paper Masking Tape Laser Engraving

Laser engraving has revolutionized the way we customize and personalize materials, offering unparalleled precision and creativity. Among the many applications of laser engraving, paper masking tape laser engraving stands out as a versatile and innovative technique. Whether you’re working with metal, acrylic, or other materials, this method allows for intricate designs, patterns, and text that can elevate your projects to new heights. In this article, we’ll explore the ins and outs of paper masking tape laser engraving, its benefits, applications, and how it compares to traditional methods.

What is Paper Masking Tape Laser Engraving?

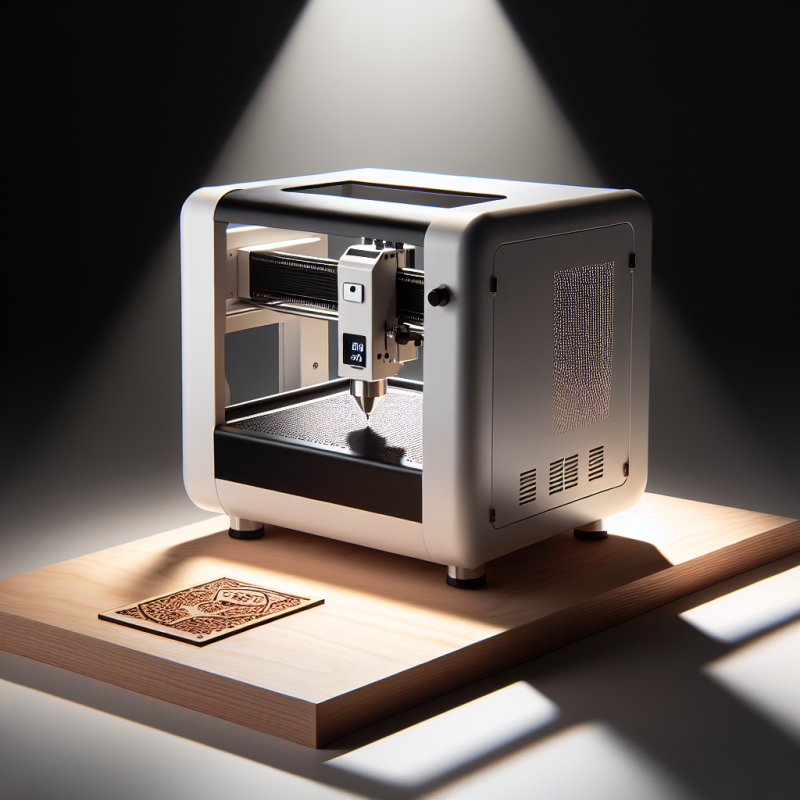

Paper masking tape laser engraving involves using a high-powered laser to etch designs or patterns onto materials that are protected by paper masking tape. This technique is particularly useful for creating precise and intricate engravings without damaging the surrounding material. The process begins with applying masking tape to the areas you wish to protect, followed by carefully aligning the laser to engrave only the exposed sections. Once the engraving is complete, the masking tape is removed, revealing a clean and polished finish.

The beauty of this method lies in its precision. By using paper masking tape, you can create complex designs with fine details that would be challenging or time-consuming to achieve manually. This makes it an ideal choice for industries such as jewelry making, sign-making, and custom tool manufacturing, where attention to detail is paramount.

Benefits of Paper Masking Tape Laser Engraving

There are numerous advantages to using paper masking tape laser engraving over traditional methods. Here are some of the key benefits:

- Precision and Accuracy: Lasers offer unmatched precision, allowing for intricate designs and text that are difficult to achieve with manual tools.

- Speed and Efficiency: Laser engraving is a fast process, reducing production time compared to traditional methods.

- Versatility: This technique can be applied to a wide range of materials, including metal, acrylic, wood, and plastic.

- Customization: With laser engraving, you can create unique designs tailored to your specific needs.

- Durability: Laser engravings are permanent and resistant to wear and tear, ensuring long-lasting results.

Applications of Paper Masking Tape Laser Engraving

Paper masking tape laser engraving has a wide range of applications across various industries. Here are some common uses:

- Jewelry Making: Engraving intricate patterns or personalized messages on jewelry pieces.

- Signage and Plaques: Creating detailed signage, awards, and plaques with custom designs.

- Custom Tool Manufacturing: Adding engravings to tools for branding or identification purposes.

- Furniture Design: Etching decorative patterns or text onto furniture surfaces.

- Automotive Industry: Engraving custom designs on car parts or accessories.

The Process of Paper Masking Tape Laser Engraving

Understanding the process of paper masking tape laser engraving is essential for achieving optimal results. Here’s a step-by-step breakdown:

- Design Creation: Start by creating your design using computer-aided design (CAD) software or graphic design tools. Ensure that your design is scalable and suitable for laser engraving.

- Material Preparation: Choose the material you wish to engrave, such as metal or acrylic. Clean the surface thoroughly to ensure proper adhesion of the masking tape.

- Masking Tape Application: Carefully apply paper masking tape to the areas you want to protect during the engraving process. This step is crucial for achieving precise and clean results.

- Laser Engraving: Set up your laser engraving machine according to the manufacturer’s instructions. Align the laser with your design and begin engraving. Adjust the power and speed settings as needed to achieve the desired depth and clarity.

- Masking Tape Removal: Once the engraving is complete, remove the masking tape carefully to reveal the finished product. Inspect the engraved areas for any imperfections or errors.

Advantages Over Traditional Engraving Methods

While traditional engraving methods have their place, paper masking tape laser engraving offers several advantages:

- Reduced Risk of Damage: By using masking tape, you can protect the surrounding material from unintended damage caused by the laser.

- Enhanced Precision: Lasers provide a level of precision that is difficult to match with manual tools.

- Faster Turnaround Time: Laser engraving is a much faster process compared to traditional methods, making it ideal for large-scale production.

- Eco-Friendly: Many laser engraving machines are energy-efficient and produce minimal waste, making them a sustainable choice.

Tips for Achieving the Best Results

To ensure your paper masking tape laser engraving projects are successful, keep these tips in mind:

- Choose the Right Masking Tape: Select a high-quality masking tape that adheres well to your material and can withstand the heat generated by the laser.

- Test Your Settings: Before engraving your final project, test your laser settings on scrap material to ensure you achieve the desired results.

- Work in a Well-Ventilated Area: Laser engraving can produce fumes and particles, so work in a well-ventilated area or use a ventilation system.

- Inspect Your Design Regularly: Monitor your engraving process to catch any errors early on and make adjustments as needed.

Frequently Asked Questions

If you’re new to paper masking tape laser engraving, you may have some questions. Here are answers to some common inquiries:

- Can I use any type of masking tape? No, it’s important to use high-quality masking tape designed for laser engraving to ensure proper adhesion and protection.

- What materials can be used with this technique? Paper masking tape laser engraving is compatible with a wide range of materials, including metal, acrylic, wood, and plastic.

- Is laser engraving safe? Yes, but it’s important to follow safety guidelines, such as wearing protective eyewear and working in a well-ventilated area.

- How long does the process take? The time required depends on the complexity of your design and the size of the material being engraved. Simple designs can be completed in minutes, while intricate patterns may take longer.

The Future of Laser Engraving

Laser engraving technology continues to evolve, offering new possibilities for creativity and precision. As advancements in laser technology continue, we can expect even more innovative applications for paper masking tape laser engraving. Whether you’re a hobbyist or a professional, embracing this technique can open up a world of opportunities for your projects.

If you’re ready to dive into the world of laser engraving, consider investing in a high-quality machine designed specifically for paper masking tape laser engraving. With the right tools and techniques, you can create stunning, custom designs that stand out.

Have you tried paper masking tape laser engraving before? Share your experiences or tips in the comments below!