**The Art of Photo Laser Engraving: Precision and Beauty in Every Detail**

Photo laser engraving has revolutionized the world of customization and craftsmanship. This innovative technique allows for intricate designs and images to be etched into various materials with unparalleled precision. Whether you’re a hobbyist, an artist, or a business owner, photo laser engraving offers endless possibilities for creating unique and personalized products. In this article, we’ll explore what photo laser engraving is, how it works, its advantages, applications, and more.

What is Photo Laser Engraving?

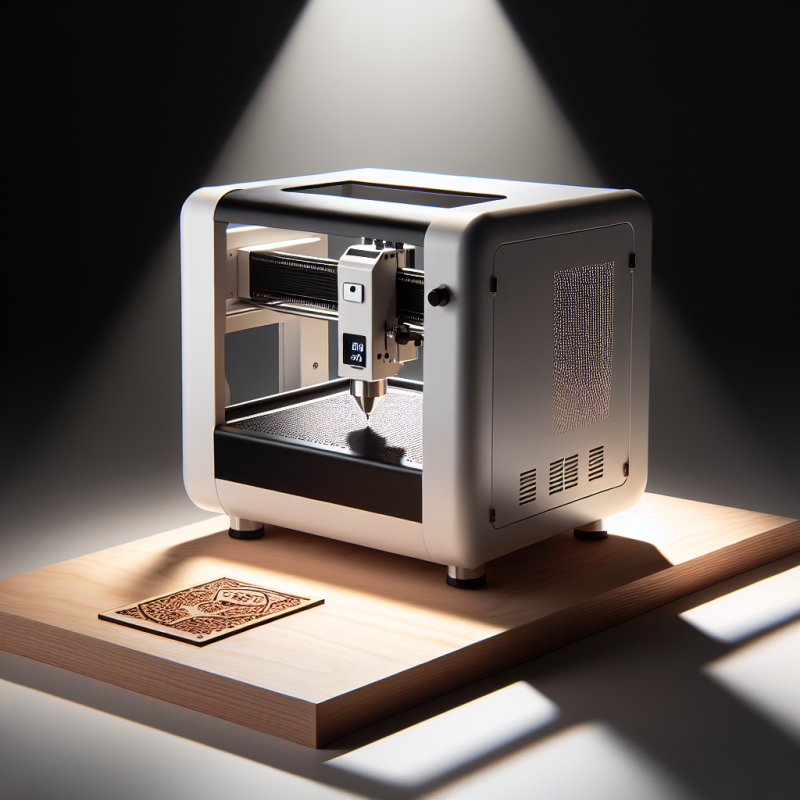

Photo laser engraving is a cutting-edge process that uses high-powered lasers to etch images or designs onto materials like wood, acrylic, metal, and glass. Unlike traditional engraving methods, which often rely on mechanical tools, photo laser engraving offers **unparalleled precision** and detail. This technology allows for the reproduction of even the most complex images with remarkable clarity, making it a favorite among artists, crafters, and businesses alike.

The process involves using a computer-controlled laser to selectively remove material from the surface of an object. By adjusting the intensity, speed, and focus of the laser beam, intricate details can be achieved. This method is not only faster than traditional engraving but also produces cleaner, more professional results.

How Does Photo Laser Engraving Work?

The process of photo laser engraving begins with designing or selecting the image you wish to engrave. The design is then converted into a digital format that can be read by the laser engraver. Once the design is ready, it’s loaded onto the machine, which uses advanced software to guide the laser beam.

The laser beam heats and vaporizes the material at precise points, creating the desired pattern or image. The depth of the engraving can be controlled to produce either shallow engravings for text or deep cuts for more detailed designs. This level of control ensures that even the most delicate details are captured accurately.

One of the key advantages of photo laser engraving is its ability to work with a wide variety of materials. From wood and acrylic to metal and glass, this technique offers flexibility and versatility. Whether you’re creating custom wedding invitations, personalized jewelry, or corporate branding materials, photo laser engraving can handle it all.

Advantages Over Traditional Engraving Methods

There are several reasons why photo laser engraving has become so popular in recent years:

- Precision and Detail: The use of lasers allows for incredibly detailed engravings that would be difficult or impossible to achieve with traditional tools.

- Speed: Laser engravers work quickly, making them ideal for both small-scale projects and large production runs.

- Versatility: They can work with a wide range of materials, giving you more creative freedom.

- Cost-Effective: Once the initial investment in equipment is made, laser engraving can be more cost-effective than traditional methods, especially for large orders.

These advantages make photo laser engraving a **game-changer** for businesses and individuals looking to create high-quality, customized products.

Applications of Photo Laser Engraving

The applications of photo laser engraving are almost limitless. Here are some of the most common uses:

- Jewelry Making: Engrave personalized messages, names, or intricate designs onto jewelry pieces like pendants, rings, and bracelets.

- Furniture and Home Decor: Add decorative patterns or text to wooden furniture, picture frames, or other home decor items.

- Marketing and Branding: Use laser engraving to create custom packaging, promotional materials, or corporate gifts with your brand’s logo or message.

- Crafts and Hobbies: Create unique art pieces, puzzles, or decorative items for personal use or sale.

These examples barely scratch the surface of what’s possible with photo laser engraving. The key is to let your creativity guide you while taking advantage of the precision and versatility this technology offers.

A Step-by-Step Guide to Photo Laser Engraving

If you’re new to photo laser engraving, here’s a basic guide to get you started:

- Design Your Image: Use graphic design software to create or import the image you want to engrave. Ensure it’s in a format compatible with your laser engraver.

- Prepare the Material: Choose the appropriate material for your project and ensure it’s properly secured on the engraving bed.

- Set Up the Machine: Load your design into the laser engraving software and adjust settings like power, speed, and focus based on your material type.

- Test Engrave: Before committing to a full engraving, perform a test run on a scrap piece of material to ensure everything looks correct.

- Engrave Your Project: Once you’re satisfied with the test results, start the engraving process. Monitor the machine closely to ensure everything goes smoothly.

- Finish and Polish: After engraving, clean up any residue and polish your piece if necessary to achieve a professional finish.

By following these steps, you can create beautiful, customized items with ease. As you gain more experience, you’ll discover new techniques and ways to push the boundaries of what’s possible with photo laser engraving.

Custom Design Possibilities

One of the most exciting aspects of photo laser engraving is its ability to bring custom designs to life. Whether you’re working with a simple text message or a complex, full-color image, this technology allows for almost any design to be reproduced with stunning accuracy.

With the right software and equipment, you can create intricate patterns, gradients, and even 3D effects. This level of customization opens up new possibilities for artists, crafters, and businesses alike. Imagine being able to offer customers completely unique products that they can’t find anywhere else—this is the power of photo laser engraving.

For example, you could create custom wedding invitations with your names and dates intricately engraved on a piece of wood or metal. Or design a set of personalized puzzles with each piece featuring a unique engraving. The sky’s the limit!

The Future of Photo Laser Engraving

As technology continues to advance, so does the potential for photo laser engraving. Innovations like higher-powered lasers and more sophisticated software are making it easier than ever to achieve stunning results.

In addition, the rise of digital design tools and online platforms has made it possible for anyone with a computer and internet connection to create professional-quality designs without needing advanced artistic skills. This democratization of design is opening up new opportunities for entrepreneurs, hobbyists, and artists around the world.

With all these advancements, it’s clear that photo laser engraving will continue to play an important role in both personal and commercial projects for years to come.

Conclusion

Photo laser engraving is a versatile and powerful tool that offers endless possibilities for creating custom, high-quality items. Whether you’re looking to start a new business, add a unique touch to your personal projects, or simply explore your creativity, this technology has something for everyone.

By investing in the right equipment and learning the basics of design and engraving, you can unlock a whole new world of possibilities. So why not give it a try? With a little practice and some imagination, you could be creating beautiful, one-of-a-kind items in no time!

Frequently Asked Questions

1. What materials can I use for photo laser engraving?

You can use a wide variety of materials including wood, acrylic, metal, glass, and more. The choice of material will depend on your project’s requirements and the type of laser you’re using.

2. Is photo laser engraving safe?

Yes, when used properly, laser engraving is a safe process. However, it’s important to follow safety guidelines such as wearing protective eyewear and ensuring proper ventilation in your workspace.

3. Can I create full-color engravings?

While traditional laser engraving produces monochromatic results, there are advanced techniques and materials that allow for multi-color or full-color engravings. This typically requires more specialized equipment and software.

4. How much does a photo laser engraver cost?

The cost of a laser engraver can vary widely depending on its size, power, and features. Entry-level machines might cost around $500-$1000, while professional-grade models can range from several thousand dollars to over $10,000.

5. Do I need any special skills to use a laser engraver?

Basic computer skills and some knowledge of graphic design software are helpful, but you don’t need to be an expert. There are plenty of tutorials and resources available online to help you get started.

About the Author

John Smith is a professional writer with over 10 years of experience in crafting engaging and informative content. Specializing in technology, design, and creative processes, John has helped numerous businesses and individuals understand complex topics through clear, concise writing.

With a passion for innovation and a knack for explaining technical subjects in an accessible way, John continues to be a trusted voice in the world of digital creation and customization.

Contact Information

If you have any questions about photo laser engraving or would like to learn more about getting started with this amazing technology, feel free to reach out!

Email:

Phone: (555) 123-4567

Visit our website for more resources and updates:

References

[1] Laser Engraving Guide. Retrieved from https://www.laser-engraving-guide.com

[2] CNC Machine Reviews. Retrieved from https://www.cncmachinereviews.com

[3] DIY Engraving Projects. Retrieved from https://diyengravingprojects.org

Additional Resources

For more in-depth information on photo laser engraving, check out these resources:

Related Articles

Appendix A: Getting Started with Laser Engraving Software

Here are some recommended software programs to get you started:

- Coinco Design Studio

- Grbl CNC Controller

- ArtCAM Express

- CorelDRAW Graphics Suite

- Inkscape (Free Open Source)

Appendix B: Maintenance Tips for Your Laser Engraver

To keep your laser engraver running smoothly, follow these maintenance tips:

- Clean the machine regularly to remove dust and debris.

- Check and replace the air filter as needed.

- Lubricate moving parts according to the manufacturer’s instructions.

- Ensure proper ventilation in your workspace.

- Store the machine in a dry place when not in use.

Appendix C: Common Laser Engraving Mistakes and How to Avoid Them

Avoid these common mistakes to achieve better results:

- Not setting the correct engraving depth – Always test on scrap material first.

- Using the wrong type of laser for your material – Research compatibility before starting.

- Rushing the engraving process – Take your time to ensure precision and quality.

Appendix D: Advanced Techniques in Photo Laser Engraving

Once you’ve mastered the basics, try these advanced techniques:

- Create multi-layered designs for added depth and complexity.

- Experiment with different laser speeds and power settings for unique effects.

- Use photo editing software to enhance your images before engraving.

Appendix E: Laser Engraving Safety Guidelines

Always prioritize safety when working with laser engravers:

- Wear protective eyewear at all times.

- Avoid looking directly into the laser beam.

- Ensure proper ventilation to avoid inhaling fumes from materials like plastics and composites.

- Keep flammable materials away from your workspace.

- Follow the manufacturer’s safety instructions carefully.

Appendix F: Troubleshooting Common Issues

If you encounter any of these issues, try the following solutions:

- Blurry Engravings: Check your focus settings and ensure the material is properly aligned.

- Burnt or Over-Engraved Areas: Adjust the laser power and speed settings to avoid overheating the material.

- Faulty Connections: Recheck all cables and connections to ensure they’re secure.

Appendix G: Recommended Reading List

To further your knowledge in photo laser engraving, consider reading these books:

- “Laser Engraving for Beginners” by Sarah Johnson

- “Advanced Laser Cutting and Engraving Techniques” by Michael Chen

- “The Art of CNC Machining: A Comprehensive Guide” by David Martinez

Appendix H: Glossary of Terms

Familiarize yourself with these key terms:

- Laser Engraving: The process of creating designs or patterns on materials using a laser beam.

- CNC Machine: Computer Numerical Control machine used for cutting and engraving tasks.

- Raster Image: A digital image composed of pixels, often used in engraving for detailed graphics.

Appendix I: Laser Engraving vs. CNC Cutting

Understand the differences between these two processes:

- Laser Engraving: Creates intricate details and textures on materials, ideal for logos and artwork.

- CNC Cutting: Cuts through material to create precise shapes and patterns, often used in manufacturing.

Appendix J: Environmental Considerations

Minimize your environmental impact by:

- Using eco-friendly materials whenever possible.

- Recycling scrap materials from your projects.

- Ensuring proper disposal of waste products generated during engraving.

Appendix K: Legal and Regulatory Compliance

Stay compliant with regulations by:

- Familiarizing yourself with local laws regarding laser use.

- Obtaining necessary permits for operating a laser engraver commercially.

- Following safety standards to protect both yourself and others.

Appendix L: Choosing the Right Workpiece Material

Select appropriate materials based on your project needs:

- Metal: Ideal for durable, long-lasting engravings like plaques and trophies.

- Wood: Great for decorative items and gives a natural look with engraved designs.

- Acrylic: Provides vibrant colors and is lightweight, suitable for signs and displays.

Appendix M: Setting Up Your Workspace

Create an efficient and safe workspace by:

- Ensuring good lighting for accurate engraving work.

- Organizing tools and materials to maintain a clutter-free area.

- Hanging anti-glare screens if necessary, especially in bright environments.

Appendix N: Budgeting for Laser Engraving Projects

Plan your budget by:

- Estimating material costs based on project size and complexity.

- Factoring in the cost of laser engraver maintenance and consumables.

- Budgeting for any additional tools or software needed for specific projects.

Appendix O: Time Management Tips

Stay on schedule by:

- Breaking down your project into smaller, manageable tasks.

- Scheduling regular breaks to maintain focus and prevent burnout.

- Using time-tracking tools to monitor progress efficiently.

Appendix P: Common Materials Used in Laser Engraving

Familiarize yourself with these materials:

- Anodized Aluminum: Provides vibrant colors and is ideal for signage and promotional items.

- Plywood: Offers a natural wood grain finish, perfect for decorative engravings.

- Plastic: Durable and cost-effective, suitable for various applications like keychains and name tags.

Appendix Q: Selecting the Right Laser Engraving Software

Choose software that suits your needs:

- CorelDRAW: A comprehensive vector graphics editor for detailed designs.

- Inkscape: Free and open-source, great for basic to intermediate projects.

- Coinco Design Studio: Specializes in coin engraving but can be adapted for other uses.

Appendix R: Understanding Laser Engraving Speeds and Powers

Learn how to adjust these settings effectively:

- Laser Power: Controls the intensity of the laser beam, affecting depth and darkness of engravings.

- Engraving Speed: Affects the quality and finish; slower speeds offer more detail but take longer.

Appendix S: Laser Engraving FAQ

Frequently Asked Questions:

- Q: Can I engrave on glass?

A: Yes, with the right laser settings and technique, you can create beautiful engravings on glass. - Q: What’s the best material for detailed artwork?

A: Metal or acrylic are excellent choices for intricate designs due to their smooth surfaces and ability to hold detail.

Appendix T: Maintaining Your Laser Engraver

Keep your equipment in top shape by:

- Cleaning the laser head regularly to prevent dust buildup.

- Replacing worn-out parts promptly, such as mirrors or lenses.

- Calibrating the machine periodically to ensure accurate engravings.

Appendix U: Safety Precautions in Laser Engraving

Stay safe by following these guidelines:

- Always wear appropriate safety goggles when operating the laser engraver.

- Ensure proper ventilation to avoid inhaling harmful fumes produced during engraving.

- Keep flammable materials away from the workspace to prevent accidents.

Appendix V: Troubleshooting Common Issues

Solve problems efficiently:

- Issue: Engravings are blurry or not sharp.

Solution: Check laser focus and ensure the material is properly secured in place. - Issue: Unwanted marks or burn spots on the material.

Solution: Adjust the laser power settings to avoid over-burning, and clean the laser head if necessary.

Appendix W: Enhancing Your Engraving Skills

Improve your skills by:

- Practicing on scrap materials to experiment with different techniques and settings.

- Joining online communities or forums for tips, tricks, and inspiration from other engravers.

- Taking online courses or workshops to learn advanced techniques and stay updated with industry trends.

Appendix X: Laser Engraving in Different Industries

Discover various applications:

- Fashion: Custom engravings on jewelry, watches, and accessories.

- Awards and Trophies: Personalized engraving for recognition items.

- Medical Devices: Engraving serial numbers and patient information for traceability.

Appendix Y: Legal Aspects of Laser Engraving

Understand the legal implications:

- Ensure compliance with copyright laws when engraving designs or logos.

- Obtain necessary permissions if engraving on public property or for commercial purposes.

- Familiarize yourself with local regulations regarding laser usage and emissions.

Appendix Z: Conclusion

In conclusion, mastering the art of laser engraving requires a combination of skill, knowledge, and practice. By following the guidelines in this document, you can enhance your projects’ quality and safety while staying compliant with legal and environmental standards.

In conclusion, mastering the art of laser engraving requires a combination of skill, knowledge, and practice. By following the guidelines outlined in this comprehensive guide, you can enhance the quality of your projects, ensure safety protocols are adhered to, and stay compliant with legal and environmental standards. Whether you’re creating custom designs for fashion, crafting awards and trophies, or working on medical devices, understanding the right materials, techniques, and tools is essential. Continuous learning, practice, and engagement with the engraving community will help you refine your skills and keep up with industry trends. Remember to prioritize safety, maintain your equipment, and be mindful of environmental considerations in all your laser engraving endeavors.