The Art of Laser Engraving Titanium: Precision and Beauty in Every Design

Laser engraving titanium has become an increasingly popular method for creating intricate designs on metal surfaces. This innovative process combines precision with creativity, offering a wide range of applications across industries. Whether you’re working on jewelry, industrial parts, or decorative items, laser engraving titanium provides unparalleled accuracy and durability. In this article, we’ll explore the benefits, techniques, and uses of laser engraving titanium, as well as answer common questions about this fascinating technology.

##

The Basics of Laser Engraving Titanium

Laser engraving titanium involves using a focused laser beam to remove or alter the surface of titanium metal. This process creates permanent designs, patterns, or text that are resistant to wear and tear. Unlike traditional methods like acid etching or mechanical engraving, laser engraving offers greater control over the design’s depth and detail.

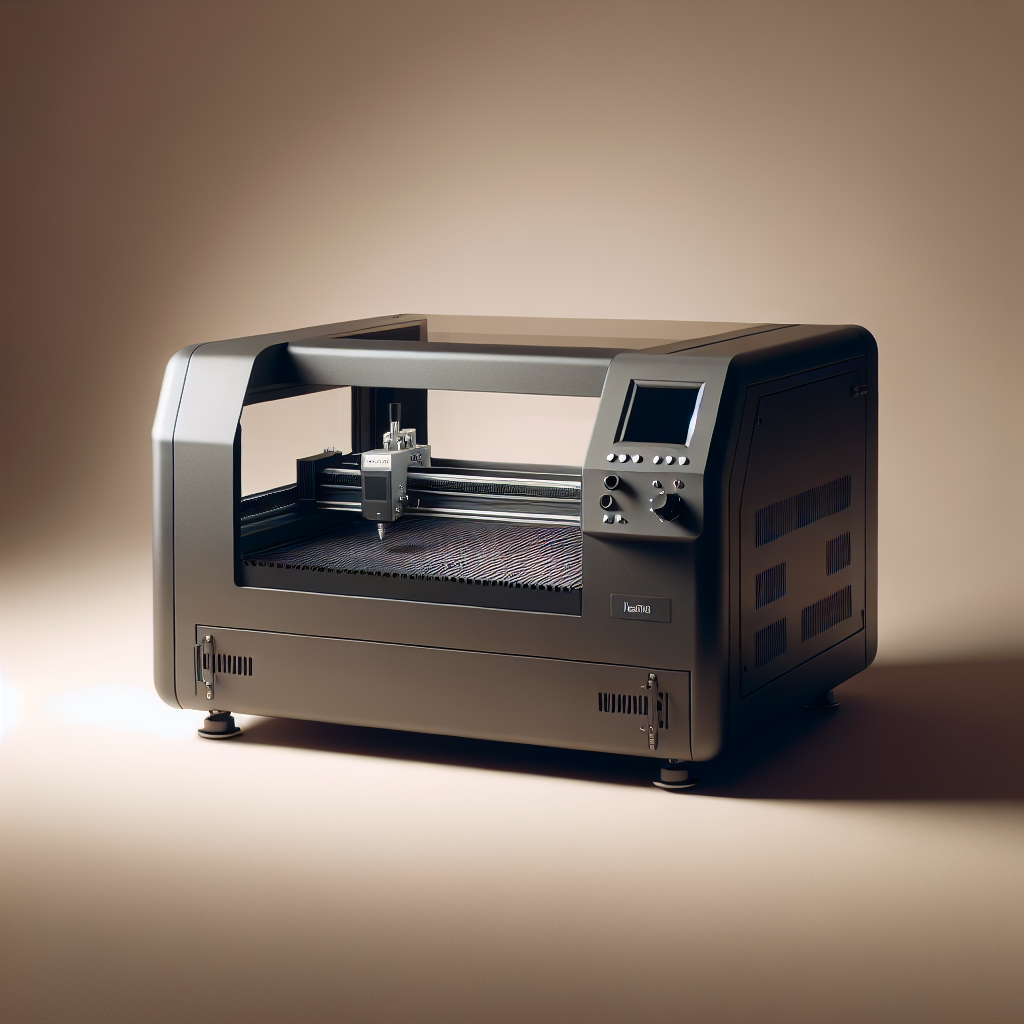

The laser engraving machine uses a highly concentrated beam of light to vaporize or melt the titanium surface. This method is not only faster but also produces cleaner results compared to other techniques. The ability to work on small details makes it ideal for creating fine engravings on jewelry, watch faces, and other precision components.

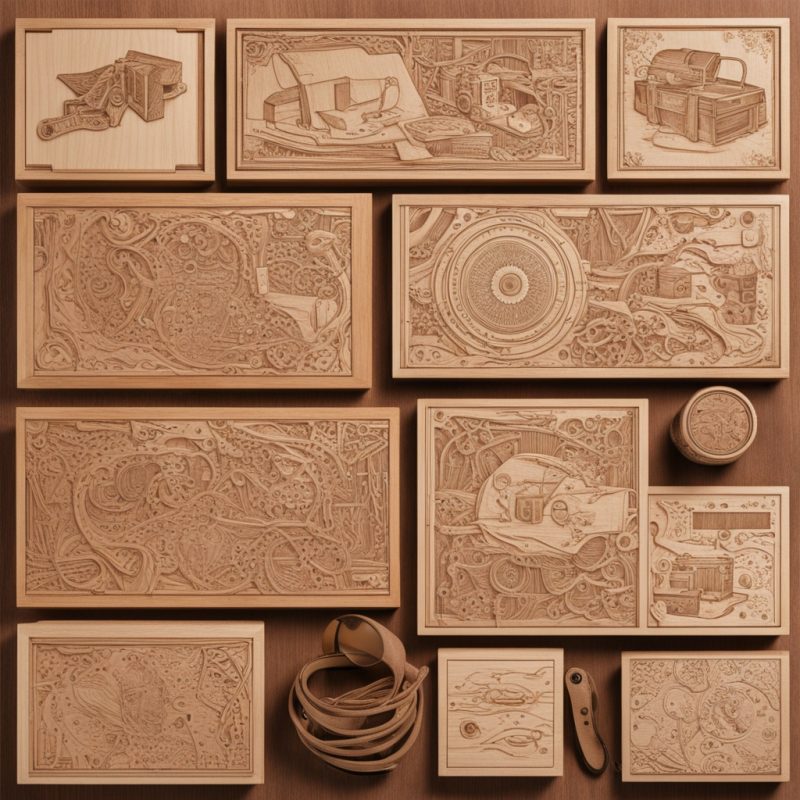

One of the key advantages of laser engraving titanium is its versatility. It can handle both simple text engravings and complex geometric patterns with ease. This makes it a favorite choice among artists, designers, and manufacturers looking to add a unique touch to their products.

##

Why Choose Laser Engraving Titanium?

Laser engraving titanium offers several benefits that set it apart from traditional methods:

- Precision and Detail: The laser beam can create intricate designs with high precision, making it perfect for detailed artwork or industrial markings.

- Durability: Engraved designs are permanent and resistant to fading, ensuring long-lasting quality.

- Speed: Compared to manual engraving, laser engraving is much faster, especially for repetitive tasks.

- Versatility: It works on various materials, including titanium, stainless steel, and even wood.

- Non-Invasive: The process doesn’t require physical contact with the material, reducing the risk of damage or deformation.

These advantages make laser engraving titanium a cost-effective and efficient solution for businesses and hobbyists alike. Whether you’re creating custom jewelry or industrial components, this technology delivers exceptional results every time.

##

Applications of Laser Engraving Titanium

Laser engraving titanium has a wide range of applications across different industries:

- Jewelry Making: Creating detailed engravings on rings, bracelets, and necklaces with intricate designs.

- Aerospace Industry: Engraving serial numbers or identification marks on aircraft components for traceability.

- Precision Engineering: Marking technical parts with complex patterns or measurements for quality control.

- Medical Devices: Engraving medical implants or instruments with patient-specific information or logos.

- Customization: Adding personal touches to items like nameplates, trophies, and decorative art pieces.

These applications highlight the versatility of laser engraving titanium. Whether you’re working in a high-tech industry or a creative field, this technology offers endless possibilities for enhancing your projects.

##

The Process of Laser Engraving Titanium

Understanding the process of laser engraving titanium is essential to maximizing its potential. Here’s a step-by-step overview:

- Design Creation: Start by creating a digital design using specialized software. This design will dictate the final look of the engraving.

- Material Preparation: Clean and prepare the titanium surface to ensure optimal results. Any dirt or grease can affect the engraving quality.

- Laser Setup: Set up the laser engraving machine according to the design specifications. Adjust parameters like power, speed, and focus distance for best results.

- Engraving Process: Run the machine and watch as the laser beam etches the design into the titanium surface. The process is quick and produces minimal waste.

- Post-Processing: After engraving, clean the area to remove any residue or debris. Depending on the application, you may also polish or finish the engraved surface for a polished look.

By following these steps, you can achieve high-quality engravings that meet your project’s requirements. The process is not only efficient but also adaptable to different materials and designs.

##

Frequently Asked Questions About Laser Engraving Titanium

If you’re new to laser engraving titanium, you might have some questions about the process. Here are answers to some of the most common ones:

- Is laser engraving titanium safe?

Yes, as long as proper safety precautions are taken. Operators should wear protective eyewear and ensure good ventilation in the workspace. - Can I engrave on different materials?

Absolutely! While titanium is a popular choice, laser engraving machines can work with various metals, plastics, and even wood. - How detailed can the engravings be?

The level of detail depends on the machine’s specifications. High-end systems can produce engravings as fine as 0.1mm in width. - Is laser engraving permanent?

Yes, once engraved, the design is permanently etched into the material and won’t fade or wear off easily. - How much does a laser engraving machine cost?

Prices vary depending on the machine’s capabilities. Basic models can start around $1000, while industrial-grade systems may cost tens of thousands of dollars.

These answers should help you feel more confident about exploring laser engraving titanium for your projects.

##

Conclusion

Laser engraving titanium is a revolutionary technology that has transformed the way we create and customize metal products. Its precision, versatility, and efficiency make it an invaluable tool for businesses and artists alike. By understanding the basics of this process and its applications, you can unlock new creative possibilities and enhance your projects with stunning engravings.

If you’re ready to take your designs to the next level, consider investing in a . With the right equipment and some practice, you’ll be able to create intricate and durable engravings on titanium and other materials. Happy engraving!