The Art of Laser Engraving for Wood: Precision Meets Creativity

Laser engraving has revolutionized the way we work with wood, offering unparalleled precision and creativity. Whether you’re a professional craftsman, an artist, or simply someone who enjoys DIY projects, laser engraving for wood opens up a world of possibilities. This technique allows you to create intricate designs, patterns, and text on wooden surfaces with ease and accuracy. In this article, we’ll explore the benefits, applications, and techniques of laser engraving for wood, as well as answer some common questions about this fascinating process.

The Benefits of Laser Engraving for Wood

Laser engraving for wood offers numerous advantages over traditional methods like carving or sanding. One of the most significant benefits is **precision**. Unlike manual tools, a laser can create incredibly fine details, even on small surfaces. This makes it ideal for tasks that require intricate designs, such as creating custom furniture, decorative items, or personalized gifts.

Another key advantage is **speed and efficiency**. A laser engraving machine can complete complex projects in a fraction of the time it would take manually. This is especially useful for businesses that need to produce large quantities of products quickly. Additionally, lasers leave a clean, polished finish on wood, eliminating the need for sanding or additional touch-ups.

Laser engraving also allows for **customization** on a scale that was previously impossible. You can easily incorporate personalized text, logos, or images into your designs. Whether you’re creating a family crest, a business logo, or a unique piece of art, laser engraving for wood ensures your project stands out.

How Does Laser Engraving Work?

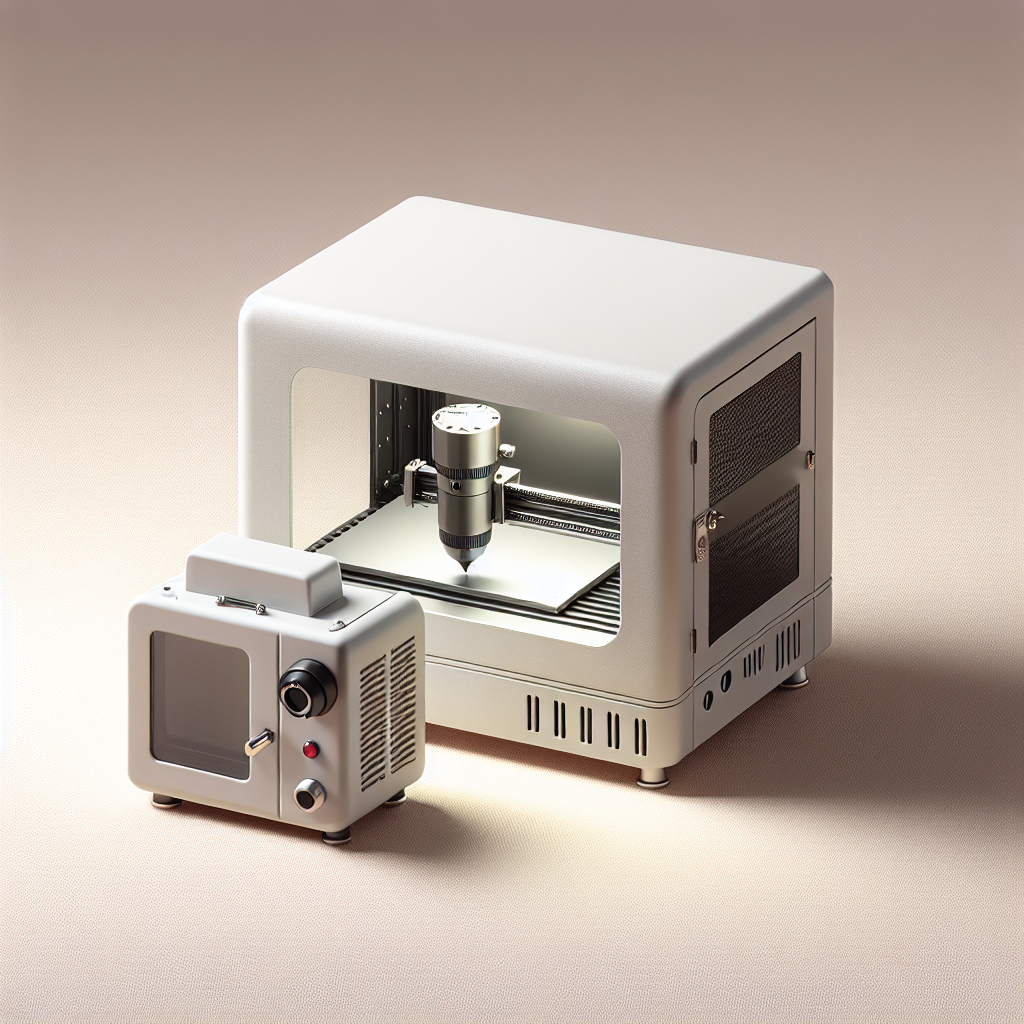

Laser engraving works by focusing a high-powered laser beam onto the surface of the wood. The laser heats the material to its burning point, removing or altering the surface layer to create the desired design. Unlike traditional carving methods, which can leave rough edges or uneven surfaces, laser engraving produces clean, precise cuts and engravings.

The process begins by importing your design into a computer software program. This software then converts the design into instructions for the laser engraver. Once the machine is set up, it uses the laser beam to etch the design onto the wood. The depth of the engraving can be adjusted depending on the intensity and duration of the laser beam, allowing for varying levels of detail and contrast.

One thing to note is that **different types of wood react differently to laser engraving**. For example, hardwoods like oak or maple are ideal for detailed engravings, while softer woods may require adjustments in laser settings to achieve the desired results. Experimenting with different materials can help you find the perfect combination for your project.

Applications of Laser Engraving for Wood

Laser engraving for wood has a wide range of applications, making it a versatile tool for both professionals and hobbyists. Some common uses include:

- Creating custom furniture with decorative patterns or initials

- Making personalized gifts, such as engraved photo frames or cutting boards

- Designing signage or menu boards for restaurants and businesses

- Producing artistic pieces, such as wood sculptures or wall art

- Add custom branding to products like jewelry boxes or wine casks

The possibilities are endless! With the right equipment and technique, you can transform ordinary wood into extraordinary works of art. Are you interested in learning more about how laser engraving for wood can enhance your projects? Let’s explore some tips and tricks to help you get started.

Tips for Getting Started with Laser Engraving

If you’re new to laser engraving, here are a few tips to keep in mind:

- **Start with simple designs**. This will give you time to learn the machine and understand how different settings affect the outcome.

- **Experiment with materials**. Not all woods respond the same way to laser engraving, so try different types of wood to see which ones work best for your project.

- **Use appropriate safety gear**. Laser engraving machines generate heat and fumes, so wear protective eyewear and ensure proper ventilation in your workspace.

- **Practice on scrap material**. Before working on your final piece, practice your design on a piece of scrap wood to fine-tune the settings and avoid mistakes.

By following these tips, you’ll be able to create stunning laser engravings for wood with confidence and precision. Remember, practice makes perfect! The more you work with the machine, the more comfortable and skilled you’ll become.

Frequently Asked Questions About Laser Engraving

Laser engraving for wood is a fascinating process, but it can also raise questions for those who are new to the technique. Here are some common questions and answers:

- **What types of wood are best for laser engraving?**

Hardwoods like oak, maple, and walnut are ideal for laser engraving due to their density and ability to hold detail. Softwoods can also be used but may require adjustments in settings. - **Can I engrave colored designs on wood?**

Yes! You can achieve colorful engravings by using a technique called **coloring**, where you add dye or stain to the engraved areas after cutting. This allows for vibrant, long-lasting results. - **Is laser engraving safe?**

Yes, as long as you follow proper safety protocols. Wear protective eyewear and ensure good ventilation to avoid inhaling fumes from the laser process. - **How much does a laser engraver cost?**

The cost of a laser engraver varies depending on its size, power, and features. Entry-level machines can be purchased for around $500, while professional-grade models may cost several thousand dollars.

By addressing these questions, we hope you feel more confident in your understanding of laser engraving for wood. If you’re ready to take the plunge, consider investing in a high-quality laser engraver to bring your creative ideas to life!

The Future of Laser Engraving

Laser engraving is constantly evolving, with new technologies and innovations emerging every year. One exciting development is the use of **3D laser engraving**, which allows for even more complex designs and multidimensional effects. As this technology becomes more accessible, it’s likely that we’ll see an increase in its use across various industries.

Another trend is the integration of laser engraving with other technologies like CNC machines and 3D printers. This creates a seamless workflow for artists and manufacturers, enabling them to design, cut, and finish projects all in one place. With these advancements, laser engraving for wood is poised to become an even more popular and versatile tool in the years to come.

Conclusion

Laser engraving for wood offers a world of possibilities for creating beautiful, customized designs. Whether you’re a professional artist, a small business owner, or simply someone with a passion for creativity, this technique can help you bring your ideas to life. By understanding the benefits, applications, and techniques involved, you’ll be well-equipped to start your own laser engraving projects.

If you’re ready to dive into the world of laser engraving, we encourage you to explore the resources available on platforms like . With a little practice and experimentation, you’ll be creating stunning works of art in no time! Are you excited to try laser engraving for wood? Let us know your thoughts below.

Happy engraving!