The Art and Science of Laser Engraving Cardboard: A Comprehensive Guide

Laser engraving cardboard has become a popular method for creating intricate designs, logos, and patterns on various surfaces. This technique offers precision, durability, and versatility, making it a favorite among crafters, hobbyists, and professionals alike. In this article, we will explore the process of laser engraving cardboard, its benefits, applications, and challenges. We will also discuss how to achieve professional-grade results using tools like the machine.

## The Basics of Laser Engraving Cardboard

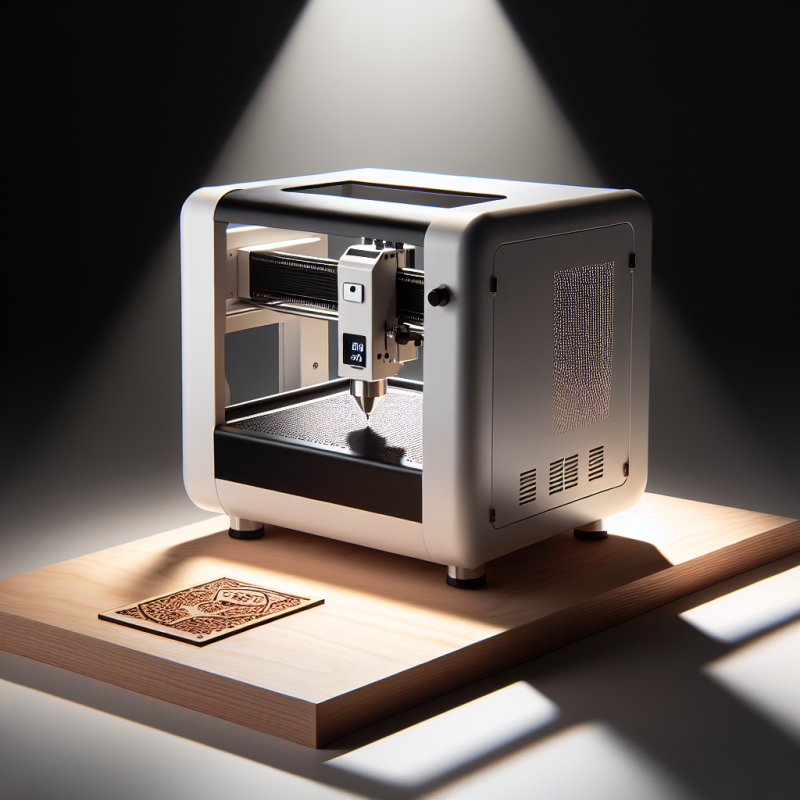

Laser engraving is a subtractive manufacturing process that uses a focused laser beam to etch or cut materials. When applied to cardboard, the laser removes material layers to create designs or patterns. Unlike traditional methods, laser engraving offers unparalleled precision and speed. Whether you’re creating custom packaging, decorative items, or promotional materials, this technique can elevate your projects to new heights.

One of the key advantages of laser engraving is its ability to work with various types of cardboard. From thin sheets to thicker boards, the right machine can handle different materials with ease. However, it’s important to note that not all lasers are created equal. The machine is specifically designed for this purpose, ensuring optimal results every time.

## Why Choose Laser Engraving Over Traditional Methods?

Traditional engraving methods often involve manual cutting or using rotary tools, which can be time-consuming and less precise. Laser engraving, on the other hand, offers several advantages:

- Precision: The laser beam is highly focused, allowing for intricate details and clean cuts.

- Customization: You can create unique designs using computer software, making it easy to adjust patterns on the fly.

- Durability: Laser-engraved markings are permanent and resistant to wear and tear.

- Speed: Compared to manual methods, laser engraving is much faster, especially for large-scale projects.

These benefits make laser engraving an ideal choice for businesses and individuals looking to produce high-quality cardboard products efficiently.

## How Does Laser Engraving Cardboard Work?

The process of laser engraving involves several steps:

- Design Creation: Start by creating or selecting a design using vector graphics software like Adobe Illustrator or CorelDRAW. The design should be scalable and compatible with your laser machine.

- Material Preparation: Choose the right type of cardboard for your project. Thicker boards are better for durable products, while thinner sheets work well for lightweight items like greeting cards.

- Laser Setup: Calibrate your laser machine according to the material thickness and design requirements. Adjust settings such as power, speed, and focus distance to ensure optimal performance.

- Engraving: Load the cardboard into the machine and start the engraving process. The laser will etch or cut the design onto the surface with pinpoint accuracy.

- Finishing Touches: Once the engraving is complete, sand or paint the surface if needed. This step enhances the appearance of the final product.

By following these steps, you can achieve professional-quality results even if you’re new to laser engraving.

## Benefits of Laser Engraving Cardboard

As mentioned earlier, laser engraving offers numerous benefits for working with cardboard. Let’s delve deeper into some of these advantages:

Precision and Detail

Laser engraving allows for extremely fine details that are impossible to achieve manually. Whether you’re creating a complex pattern or a simple logo, the laser ensures clean lines and sharp edges.

Versatility

Cardboard is a versatile material that can be used in various applications, from packaging to art. Laser engraving enhances this versatility by enabling creative designs that suit different purposes.

Durability

Laser-engraved markings are permanent and resistant to fading or chipping, making them ideal for long-lasting products like business cards, promotional items, and decorative pieces.

## Applications of Laser Engraving Cardboard

The applications of laser engraving cardboard are vast. Here are some common uses:

- Packaging: Create custom boxes, gift packaging, and product displays with intricate designs.

- Decorative Items: Make personalized coasters, wall art, and home decor pieces.

- Signage: Produce signs, labels, and directional markers with professional-grade text and graphics.

- Craft Projects: Use laser engraving to add unique details to handmade crafts, such as greeting cards or scrapbook pages.

These applications demonstrate how laser engraving can transform simple cardboard into functional and aesthetic products.

## Challenges of Laser Engraving Cardboard

While laser engraving offers many benefits, there are also some challenges to consider:

Material Limitations

Not all types of cardboard work well with laser engraving. Some materials may burn or discolor during the process, especially if they contain glue or wax.

Maintenance and Costs

Laser machines require regular maintenance to ensure optimal performance. Additionally, purchasing a high-quality machine like the can be an initial investment.

Safety Precautions

Working with lasers requires proper safety measures, including protective eyewear and a well-ventilated workspace. Improper handling can lead to accidents or damage to the machine.

## Tips for Achieving Professional Results

To get the best results from your laser engraving project, keep these tips in mind:

- Test First: Always test your design on a small piece of cardboard before committing to a full-scale project. This helps you adjust settings and ensure everything works as expected.

- Use the Right Software: Invest in reliable vector graphics software that supports laser cutting and engraving. This will give you more control over your designs.

- Experiment with Layers: Layering different textures or patterns can add depth and interest to your projects.

- Clean the Machine Regularly: Dust and debris can affect the performance of your laser machine. Clean it after each use to maintain its efficiency.

## Conclusion

Laser engraving cardboard is a powerful technique that combines precision, creativity, and functionality. With the right tools and techniques, you can produce stunning designs that meet both aesthetic and practical needs. Whether you’re a hobbyist or a professional, investing in a high-quality machine like the can open up new possibilities for your projects.

If you’re ready to take your cardboard crafting to the next level, why not try laser engraving today? With a little practice and experimentation, you’ll be creating beautiful, durable pieces in no time!