Mastering Laser Engraving: A Comprehensive Guide to Woodworking with Precision

Laser engraving has revolutionized the way we approach woodworking and creative design. With its precision, versatility, and ability to create intricate designs, laser engraving has become a go-to method for both hobbyists and professionals alike. If you’re looking to delve into the world of laser engraving or enhance your current skills, this guide will walk you through everything you need to know about *laser engrave* techniques, tools, and applications.

## What is Laser Engraving?

Laser engraving is a process that uses a focused beam of light to etch designs, patterns, or text onto various materials. Unlike traditional engraving methods that use mechanical cutting tools, laser engraving offers unparalleled precision and control. This method is particularly popular for woodworking due to its ability to create intricate details without causing damage to the material.

The process involves directing a high-powered laser at the surface of the wood, burning away layers to reveal the desired design. The result is a polished, professional finish that can be customized to suit any project. Whether you’re creating decorative items, personalized gifts, or functional furniture pieces, *laser engrave* technology opens up a world of possibilities.

## Benefits of Laser Engraving

Before diving into the technical aspects, it’s essential to understand why laser engraving has become so popular. Here are some key benefits:

- Precision and Accuracy: Laser engraving allows for extremely fine details, making it ideal for complex designs.

- Versatility: It can be used on various materials, including wood, metal, plastic, and more.

- Speed: Compared to traditional methods, laser engraving is faster and more efficient.

- Customization: You can create unique, personalized designs that stand out.

- Non-Invasive: The laser beam doesn’t physically touch the material, reducing the risk of damage.

These benefits make laser engraving a preferred choice for both small-scale projects and large-scale production.

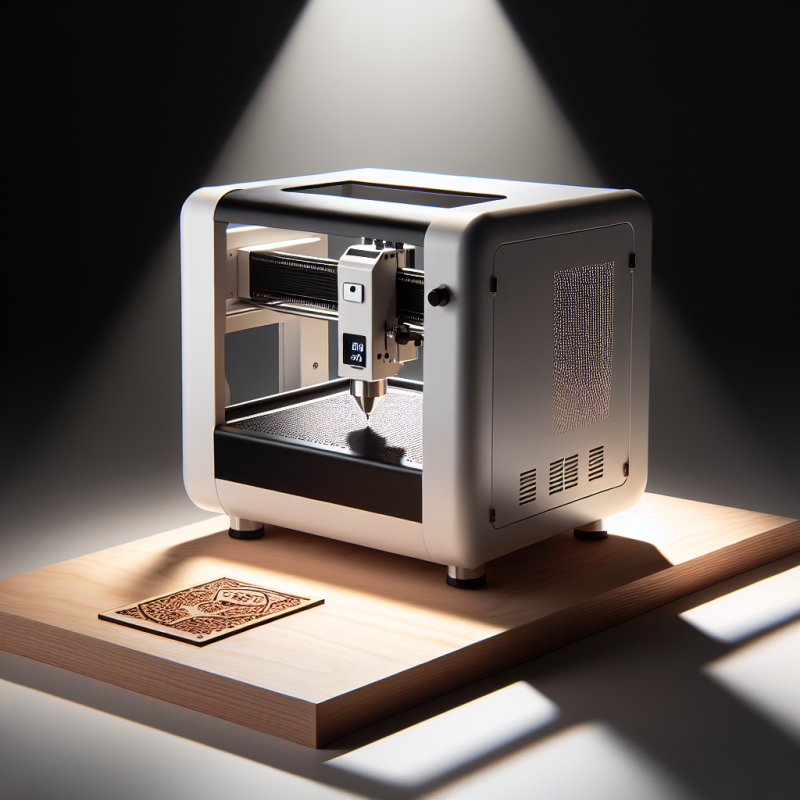

## Choosing the Right Laser Engraving Machine

One of the first steps in mastering laser engraving is selecting the right machine. A high-quality *laser cutter machine* is essential for achieving professional results. When choosing a laser cutter, consider factors such as power output, compatibility with materials, and ease of use.

For woodworking specifically, look for machines designed to handle wood without causing burn marks or uneven cuts. The laser engrave machine mentioned earlier is an excellent option due to its precision and versatility. It’s designed to handle various types of wood, from thin veneers to thick planks, ensuring consistent results every time.

## Essential Laser Engraving Techniques

Mastery of laser engraving requires understanding the techniques that set it apart from other methods. Here are some key techniques to explore:

### 1. **Vector vs. Raster Engraving**

Vector engraving is ideal for creating clean, bold lines and shapes. It works by following a path without repeatedly tracing over areas, making it perfect for logos or geometric designs. On the other hand, raster engraving is used for creating shaded images or detailed artwork. This method involves burning pixels in a grid pattern to build up the design gradually.

### 2. **Depth Control**

The depth of the engrave can be adjusted to achieve different effects. Shallow engravings are great for subtle designs, while deeper cuts create more pronounced textures. Experimenting with depth can help you find the perfect balance for your project.

### 3. **Layering**

Layering involves creating multiple passes over the same area to build up intricate details. This technique is particularly useful for adding depth and dimension to designs, such as in artistic woodwork or decorative items.

## Applications of Laser Engraving

Laser engraving is not limited to woodworking; it has a wide range of applications across various industries. Here are some popular uses:

### 1. **Custom Furniture**

Add a personal touch to furniture by engraving names, dates, or artistic patterns. This technique can transform plain wood into a unique, handcrafted piece.

### 2. **Jewelry Making**

Laser engraving is perfect for creating delicate designs on jewelry. It allows for intricate details that would be difficult to achieve with traditional methods.

### 3. **Signage and Plaques**

Create professional-looking signs, plaques, or awards with crisp, clear text and images. Laser engraving ensures longevity and durability, making it ideal for outdoor applications.

### 4. **Artistic Expression**

Wood artists can use laser engraving to create stunning pieces of art. From abstract designs to realistic portraits, the possibilities are endless.

## Maintenance Tips for Your Laser Engraving Machine

To ensure your *laser cutter machine* remains in top condition, regular maintenance is essential. Here are some tips:

- Clean the Lens: Dust and debris can accumulate on the lens, reducing its efficiency. Clean it regularly using a soft cloth and lens cleaner.

- Check Focal Point: Ensure the laser beam is focused correctly to maintain precision. Misalignment can lead to blurry or uneven engravings.

- Update Software: Keep your machine’s software up-to-date to take advantage of new features and improvements.

- Handle Materials Carefully: Always use the recommended materials to prevent damage to the laser head or optics.

## Common Mistakes to Avoid

Even experienced users can make mistakes when working with laser engraving machines. Here are some common pitfalls to watch out for:

- Inconsistent Speeds: Adjusting the speed incorrectly can lead to uneven engravings or burns.

- Improper Material Setup: Using the wrong material or not securing it properly can result in poor quality output.

- Neglecting Calibration: Failing to calibrate the machine regularly can lead to inaccuracies in engraving.

- Overloading the Machine: Exceeding the recommended power settings can damage both the machine and the material.

## Conclusion

Laser engraving is a powerful tool that has revolutionized woodworking and various other industries. With its precision, versatility, and speed, it offers endless possibilities for creating unique and professional projects. By selecting the right machine, mastering essential techniques, and maintaining your equipment, you can unlock the full potential of laser engraving.

If you’re ready to take your woodworking projects to the next level, consider investing in a high-quality

Related Articles