Mastering Acrylic Laser Engraving: A Comprehensive Guide to Machines and Techniques

Laser engraving acrylic has become a cornerstone of modern manufacturing and creative design. With its ability to produce crisp, detailed, and permanent markings, laser technology is revolutionizing industries ranging from signage to jewelry. But how do you choose the right laser engraving acrylic machine, and what techniques ensure flawless results? This article dives deep into the essentials of acrylic laser engraving, exploring machine types, best practices, and expert tips.

Why Acrylic is Ideal for Laser Engraving

Acrylic, also known as PMMA (polymethyl methacrylate), is a versatile material prized for its clarity, durability, and ease of customization. When exposed to a laser beam, acrylic undergoes a process called “vaporization,” where the focused energy melts and evaporates the material to create precise engravings. Unlike traditional methods, laser engraving acrylic produces smooth edges and intricate details without physical contact, reducing the risk of cracks or distortions.

Key advantages of using acrylic for laser projects include:

- High contrast: Engraved areas scatter light, creating a frosted effect that contrasts beautifully with untouched surfaces.

- Durability: Acrylic resists fading, making it ideal for outdoor signage or long-lasting products.

- Versatility: Available in cast and extruded varieties, acrylic accommodates everything from laser engraving acrylic artworks to industrial components.

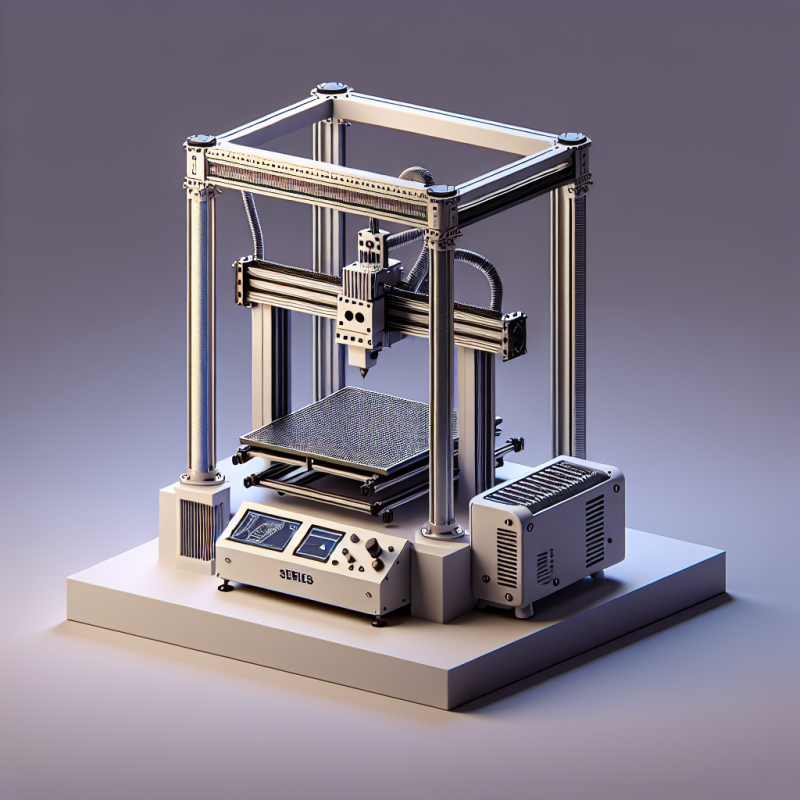

Choosing the Right Laser Engraving Machine for Acrylic

Not all laser engravers are created equal. The optimal machine depends on your project scale, budget, and desired precision. Below are the three most common types used for laser engraving acrylic:

- CO2 Lasers: These machines excel at cutting and engraving non-metallic materials. With wavelengths around 10.6 microns, CO2 lasers efficiently vaporize acrylic, delivering smooth finishes. They’re ideal for large-scale production.

- Diode Lasers: Compact and affordable, diode lasers like the LaserHawk LX1 PMag are perfect for hobbyists and small businesses. While slower than CO2 systems, they achieve remarkable detail on thin acrylic sheets.

- Fiber Lasers: Primarily used for metals, fiber lasers can also engrave acrylic but require careful power adjustments to avoid melting.

Question: Which laser type is best for double-color acrylic? For dual-layer acrylic (e.g., black-on-clear), diode lasers like the LaserHawk LX1 PMag are unmatched. Their precision ensures clean removal of the top layer while preserving the underlying color.

Key Features to Look for in an Acrylic Laser Engraver

When investing in a laser engraving acrylic machine, prioritize these features:

- Wavelength: 450nm (diode) or 10.6µm (CO2) are optimal for acrylic.

- Power Output: 5W–40W for diode lasers; 30W–100W for CO2 systems.

- Bed Size: Match the workspace to your project dimensions.

- Cooling System: Air-assisted cooling prevents overheating during prolonged use.

- Software Compatibility: Ensure the machine supports industry-standard design tools like LightBurn or CorelDRAW.

Step-by-Step Guide to Laser Engraving Acrylic

Follow these steps to achieve professional-grade results:

- Material Preparation: Clean the acrylic surface with isopropyl alcohol to remove dust and oils.

- Design Setup: Import vector graphics into your laser software. Use high-contrast images for crisp engravings.

- Machine Calibration: Adjust the focal length and test settings on a scrap piece. For cast acrylic, start with 20% speed and 80% power on a 40W CO2 laser.

- Engraving: Initiate the process and monitor the first pass. Adjust parameters if the result is too shallow or charred.

- Post-Processing: Remove protective film (if any) and polish edges with a flame for a glass-like finish.

Question: Why does cast acrylic perform better than extruded acrylic in laser engraving? Cast acrylic has uniform molecular structure, ensuring consistent melting and smoother engravings. Extruded acrylic often contains impurities that cause uneven results.

Troubleshooting Common Issues in Acrylic Laser Engraving

Even experts encounter challenges. Here’s how to resolve frequent problems:

- Cloudy Engravings: Caused by excessive heat. Reduce power or increase speed.

- Burn Marks: Use masking tape to protect the surface and enable air assist to blow away debris.

- Incomplete Cuts: Check lens focus and material thickness. Thicker acrylic requires multiple passes.

Applications of Laser-Engraved Acrylic

The versatility of laser engraving acrylic extends to countless industries:

- Retail: Customized keychains, trophies, and signage.

- Architecture: Scale models and decorative panels.

- Healthcare: Medical device labels and surgical tools.

- Art & Fashion: Intricate jewelry and illuminated sculptures.

Future Trends in Acrylic Laser Engraving Technology

Innovations are reshaping the landscape of laser engraving acrylic. Hybrid machines combining diode and CO2 lasers offer unmatched flexibility, while AI-powered software automates parameter adjustments based on material scans. Additionally, eco-friendly acrylics made from recycled materials are gaining traction, demanding advanced engraving techniques to maintain quality.

Question: Will low-cost diode lasers replace industrial CO2 systems? While diode lasers like the LaserHawk LX1 PMag are closing the performance gap, CO2 lasers remain superior for high-volume, thick-material applications. However, diode technology is rapidly evolving, making it a viable option for many businesses.

Conclusion

Mastering laser engraving acrylic requires the right equipment, meticulous preparation, and a deep understanding of material behavior. Whether you’re a hobbyist exploring diode lasers or an industrial manufacturer relying on CO2 systems, this guide equips you with the knowledge to elevate your projects. As technology advances, staying informed about trends like AI integration and sustainable materials will ensure your work remains cutting-edge.

Final Question: How can you test a laser engraver’s compatibility with acrylic before purchasing? Always request a sample engraving or review case studies from manufacturers. For instance, the LaserHawk LX1 PMag offers downloadable test files to preview its performance on dual-color acrylic.