Laser Engraver Designs: Revolutionizing Personal and Professional Creativity

Laser Engraving Technology and Applications

Laser engraving technology has revolutionized the way we personalize and create items across various industries. This advanced method of marking or cutting materials involves using a high-energy laser beam to remove layers of material, revealing intricate designs, text, or images. Laser engraver designs have evolved significantly, offering precision, speed, and versatility that cater to a wide range of applications.

From personalized gifts and jewelry to industrial prototyping and signage, laser engraving offers unparalleled detail and accuracy. It is commonly used in art and craft studios, educational institutions, small businesses, and large-scale manufacturing settings. Whether you are looking to create custom logos, engrave serial numbers, or personalize items with unique designs, laser engraving machines provide a reliable and efficient solution.

- Personalized Gifts: Engrave names, dates, or messages on items like photo frames, keychains, and cutting boards.

- Art and Craft: Create intricate designs on wood, leather, glass, and other materials for unique artistic pieces.

- Industrial Prototyping: Use laser engravers for rapid prototyping, marking components, and creating precision parts.

- Signage: Produce high-quality, durable signs and plaques with detailed graphics and text.

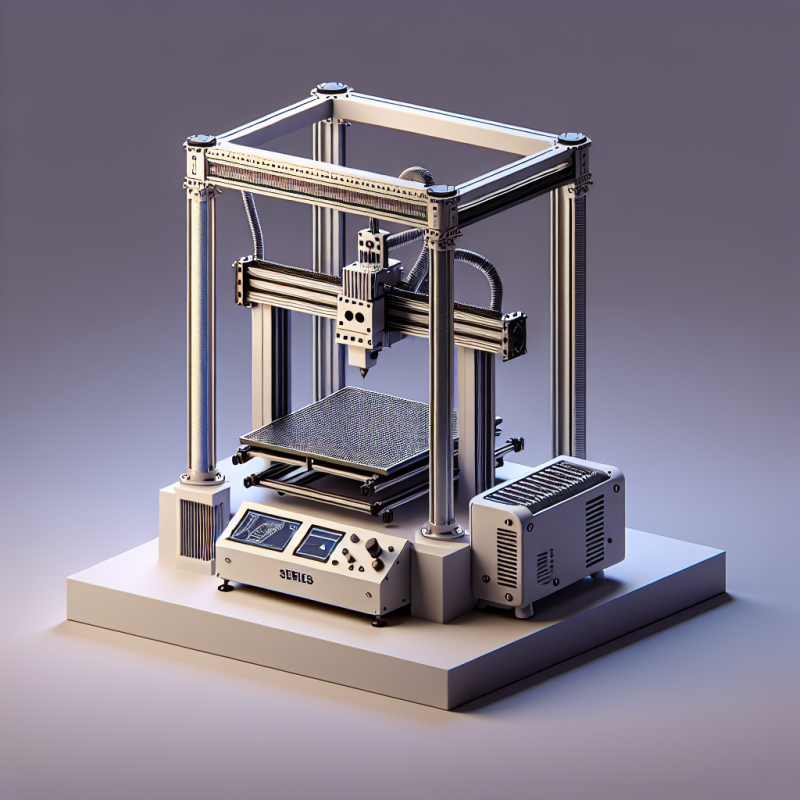

Machine Specifications and Features

When considering laser engraver designs, it’s essential to understand the specifications and features that determine performance and capability. Modern laser engraving machines come with a variety of configurations to suit different needs.

Power and Beam Quality: The power of the laser beam determines the speed and depth of engraving. Higher-power machines can cut thicker materials and work faster. Beam quality affects precision and edge quality. Look for machines with a stable, focused beam for the best results.

Workspace Size: The working area of the machine determines the maximum size of items you can engrave. For personal use, a smaller workspace may suffice, while professionals may need a larger area to accommodate larger projects.

Software Compatibility: User-friendly software is crucial for designing and controlling the laser engraving process. Look for machines that support popular design software, such as Adobe Illustrator, CorelDRAW, and Inkscape, and offer intuitive control interfaces.

Connectivity: Modern laser engravers often come with Wi-Fi and USB connectivity options, allowing for seamless integration with computers and mobile devices.

Material Compatibility

One of the most significant advantages of laser engraving is its versatility in terms of material compatibility. Different materials respond differently to the laser beam, and understanding these interactions is key to achieving the desired results.

- Wood: A popular choice for laser engraving due to its natural beauty and ability to accept intricate designs.

- Leather: Laser engraving leather creates clean, precise lines and patterns, ideal for personalizing bags, wallets, and accessories.

- Acrylic: Known for its transparency and vibrant colors, acrylic can be laser cut and engraved to create stunning visual effects.

- Metal: While metals reflect laser beams, special coatings or marking sprays can make them laser-engravable, allowing for detailed text and graphics.

- Glass: Laser engraving glass creates frosted or etched designs, adding a touch of elegance to decorative items.

Safety Considerations

Operating a laser engraver safely is paramount. High-energy laser beams can cause serious eye and skin injuries, so it’s crucial to follow safety protocols.

- Eye Protection: Always wear laser-safe glasses when operating the machine or viewing the laser beam.

- Ventilation: Ensure proper ventilation to prevent the accumulation of laser-generated fumes and particles.

- Fire Safety: Keep a fire extinguisher nearby and avoid leaving the machine unattended during operation.

- Training: Provide comprehensive training to all operators to ensure they understand the machine’s safety features and emergency procedures.

Industry Best Practices

Adhering to industry best practices can optimize the performance and longevity of your laser engraving machine.

- Regular Maintenance: Clean the lens and mirrors regularly to maintain beam quality. Check for and replace worn-out parts promptly.

- Material Preparation: Ensure materials are properly secured and aligned before starting the engraving process to avoid misalignments or damage.

- Software Optimization: Use software features like vectorization and rasterization to optimize design files for laser engraving.

- Test Runs: Always perform test runs on scrap material to adjust settings for the best results before proceeding with the final piece.

Cost-Benefit Analysis

Investing in a laser engraver can offer significant benefits, but it’s important to consider the costs involved. While the initial purchase price may seem high, the long-term savings and increased productivity can justify the investment.

Initial Costs: Consider the cost of the machine, accessories, and software. Look for machines that offer a good balance between price and features.

Operating Costs: Factor in consumables like lenses, mirrors, and marking materials. High-quality machines with durable components can reduce these costs over time.

Return on Investment: Evaluate the potential revenue from laser-engraved products. Personalized items often command a premium, and the ability to offer custom services can attract more customers.

Maintenance Tips

Proper maintenance is essential for keeping your laser engraving machine in top condition. Regular checks and adjustments can prevent costly repairs and downtime.

- Daily Checks: Inspect the lens and mirrors for dust or debris. Ensure all connections are secure.

- Weekly Cleaning: Use compressed air or lens cleaning paper to remove dust from the optics. Clean the machine’s exterior with a damp cloth.

- Monthly Inspections:

- Software Updates:

Check for any signs of wear or damage on moving parts. Lubricate mechanical components as needed.

Keep the machine’s software up-to-date to benefit from the latest features and bug fixes.

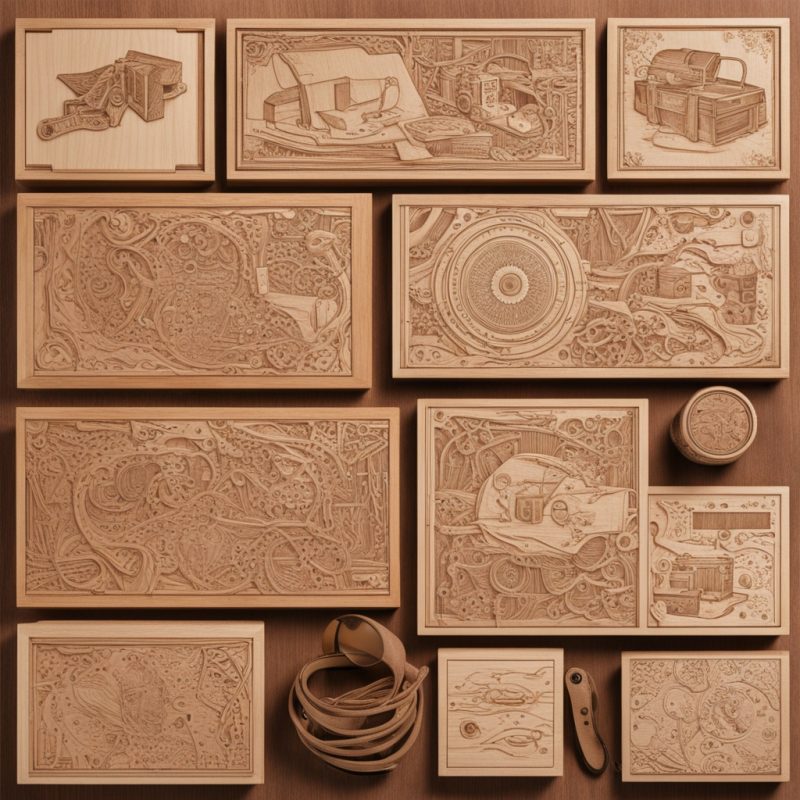

Project Ideas and Tutorials

Once you have your laser engraver set up, the possibilities for creativity are endless. Here are some project ideas and tutorials to get you started:

- Personalized Cutting Boards: Design and engrave custom cutting boards with family names, dates, or monograms. This is a great gift idea for weddings, anniversaries, or housewarming parties.

- Engraved Leather Wallets: Use vector graphics to create unique designs on leather wallets. This project combines functionality with personal style.

- Custom Jewelry: Engrave names, initials, or special dates on metal jewelry pieces. This adds a personal touch to any accessory.

- Acrylic Signs: Create vibrant, eye-catching signs by combining laser cutting and engraving on acrylic sheets. This is perfect for business logos, event signage, or home decor.

- Wooden Ornaments: Design and laser-cut intricate patterns on wooden ornaments for the holidays. These make wonderful gifts and decorations.

For tutorials