Laser Engraved Gifts: Unveiling the Potential of Laser Engraving Machines

Introduction

Laser engraved gifts have become increasingly popular due to their precision, detail, and personalization capabilities. From custom jewelry to engraved wooden boxes, the applications of laser engraving technology are vast and diverse. This article delves into the intricacies of laser engraving machines, exploring their specifications, features, material compatibility, safety considerations, industry best practices, cost-benefit analysis, maintenance tips, and inspiring project ideas.

Laser Engraving Technology and Applications

Laser engraving technology utilizes a high-energy laser beam to create intricate designs, text, or images on various materials. The process involves focusing the laser beam onto the surface of the material, which then vaporizes or alters the material to create the desired mark. This technology is widely used for creating laser engraved gifts, promotional items, art pieces, and functional prototypes.

Some of the most popular applications include:

- Personalized Jewelry: Engraving names, dates, or initials onto jewelry pieces adds a touch of personalization.

- Custom Awards and Trophies: Engraving logos, team names, or individual achievements onto awards enhances their significance.

- Woodworking Projects: From cutting intricate patterns to engraving text onto wooden boxes, laser engravers excel in woodworking.

- Leather Goods: Customizing leather wallets, belts, and bags with unique designs or text is a growing trend.

- Acrylic and Glass Etching: Creating frosted designs or text within transparent materials adds a striking visual effect.

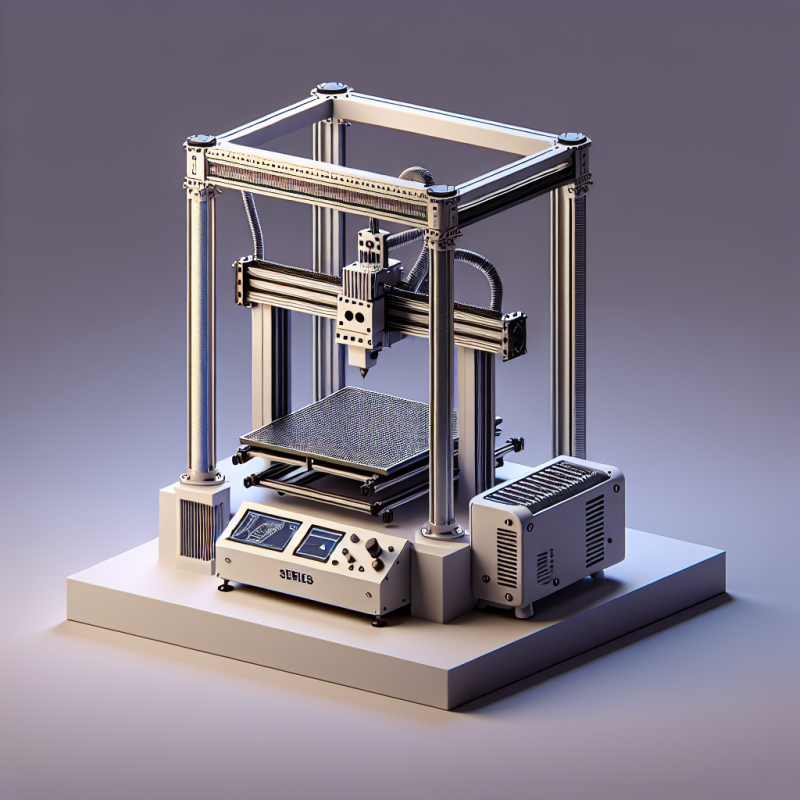

Machine Specifications and Features

When choosing a laser engraving machine for creating laser engraved gifts, several specifications and features are crucial:

- Laser Power: Higher power lasers can cut thicker materials and engrave faster. Machines like the XTool Laser Engraver offer varying power levels to suit different needs.

- Workspace Size: The workspace determines the maximum size of the material that can be engraved. Larger workspaces accommodate bigger projects.

- Resolution: Higher resolution ensures finer details and clearer text. Look for machines with resolutions that meet your specific requirements.

- Software Compatibility: User-friendly software that supports various file formats (such as SVG, PNG, and JPEG) simplifies the design process.

- Safety Features: Essential safety features include emergency stop buttons, enclosed work areas, and exhaust systems to vent harmful fumes.

Material Compatibility

Laser engravers are compatible with a wide range of materials, making them versatile for creating diverse laser engraved gifts. Some of the most commonly used materials include:

- Wood: From plywood to hardwood, wood is a popular choice for its ease of engraving and aesthetic appeal.

- Leather: Soft and supple leathers are ideal for laser cutting and engraving, producing clean and precise results.

- Acrylic and Glass: These materials can be etched to create frosted designs or intricate patterns.

- Metals: Although laser cutting metals is challenging, many machines can engrave metal surfaces with precision.

- Paper and Cardboard: Perfect for creating intricate papercraft and personalized greeting cards.

Safety Considerations

Operating a laser engraving machine safely is paramount. Here are some essential safety considerations:

- Personal Protective Equipment (PPE): Always wear laser safety goggles, gloves, and appropriate clothing to protect yourself from laser radiation and flying debris.

- Ventilation: Ensure adequate ventilation to prevent the buildup of harmful fumes and particles.

- Fire Safety: Keep a fire extinguisher nearby and have a clear escape route in case of a fire.

- Training: All operators should receive proper training on how to use the machine safely.

- Regular Maintenance: Keep the machine clean and well-maintained to prevent accidents.

Industry Best Practices

Adopting industry best practices can optimize the performance and longevity of your laser engraver:

- Material Preparation: Ensure materials are properly secured and free of contaminants that could cause fires or poor engraving quality.

- Software Optimization: Use software features to optimize the engraving path, reducing processing time and wear and tear on the machine.

- Regular Calibration: Calibrate the machine regularly to maintain accuracy.

- Material Testing: Test different settings on scrap material before starting a project to ensure the best results.

- Documentation: Keep detailed records of settings, material types, and project outcomes for future reference.

Cost-Benefit Analysis

Investing in a laser engraving machine can be costly, but it offers several benefits that can justify the expenditure:

- Versatility: A single machine can handle a variety of materials and projects, reducing the need for specialized equipment.

- Precision: Laser engraving offers unparalleled precision, ensuring high-quality results.

- Scalability: Machines can be upgraded to accommodate larger workspaces or more powerful lasers as needs grow.

- Time-Saving: Automation and high-speed engraving capabilities reduce labor costs and production time.

- Market Appeal: Personalized and custom-made laser engraved gifts have high market appeal, increasing sales potential.

Maintenance Tips

Proper maintenance is crucial for keeping your laser engraver in top condition:

- Clean the Lens: Regularly clean the laser lens to prevent dust and debris from affecting the beam quality.

- Lubricate Moving Parts: Keep moving parts well-lubricated to reduce friction and wear.

- Inspect Cables and Connections: Regularly check cables and connections for damage or loosening.

- Filter Exhaust Systems: Clean or replace exhaust filters regularly to prevent clogging.

- Software Updates: Ensure the machine’s software is up-to-date to benefit from the latest features and bug fixes.

Project Ideas and Tutorials

Here are some inspiring project ideas and tutorials to get you started with creating laser engraved gifts:

- Personalized Cutting Boards: Engrave family names, monograms, or inspirational quotes onto cutting boards for a thoughtful kitchen gift.

- Custom Keychains: Create unique keychains by engraving metal or acrylic tags with names, dates, or logos.

- Photo Engravings: Convert photos into grayscale images and engrave them onto wood or acrylic for personalized wall art.

- Engraved Jewelry: Design and engrave pendants, bracelets, or rings with meaningful symbols or text.

- Engraved Wine Bottles: