Laser Engrave Knife Laser Engraving Machines: Unveiling Precision and Creativity

Laser engraving technology has revolutionized the way we create intricate designs, personalized items, and prototypes. Among the various types of laser engraving machines available, those equipped with laser engrave knives stand out for their precision, versatility, and ability to handle a wide range of materials. This article delves into the intricacies of laser engrave knife laser engraving machines, exploring their technology, applications, specifications, safety considerations, industry practices, cost-benefit analysis, maintenance tips, and project ideas.

Laser Engraving Technology and Applications

Laser engraving involves using a high-intensity laser beam to remove material from a surface, creating a design or text. The process is non-contact, meaning there is no physical tool touching the workpiece, which minimizes wear and tear and allows for extreme precision. Laser engrave knives are particularly effective for detailed work, as they can produce very fine lines and intricate patterns.

Applications of laser engrave knives span numerous industries, including:

- Jewelry Making: Engraving names, dates, or symbols onto jewelry pieces.

- Personalization: Creating custom gifts, such as engraved pens, keychains, or photo frames.

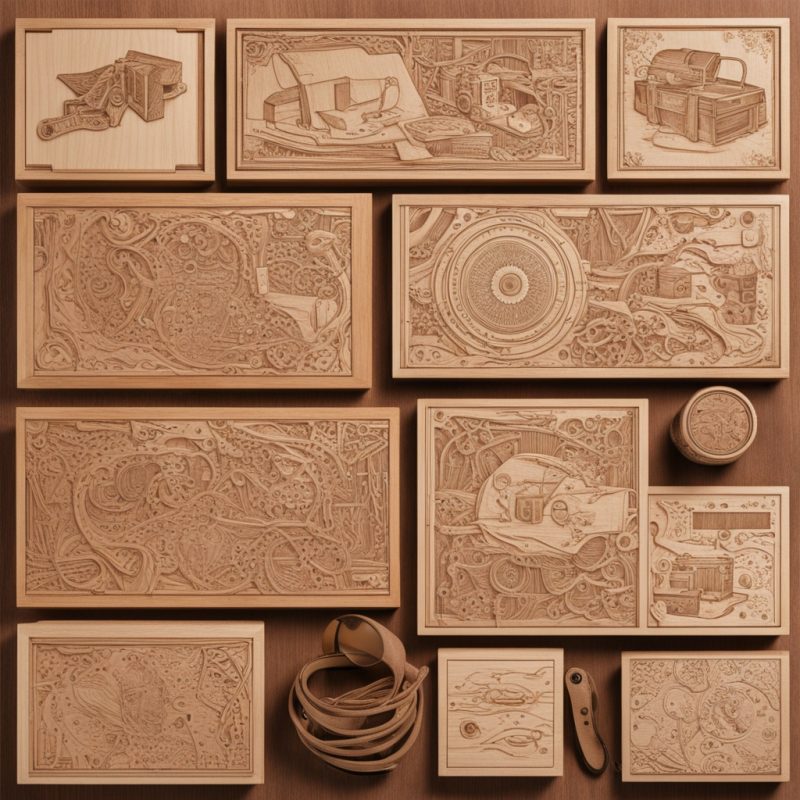

- Art and Craft: Producing intricate designs on wood, leather, or acrylic.

- Industrial Marking: Labeling tools, parts, and equipment with serial numbers, barcodes, or logos.

- Prototyping: Making detailed models and prototypes for design verification.

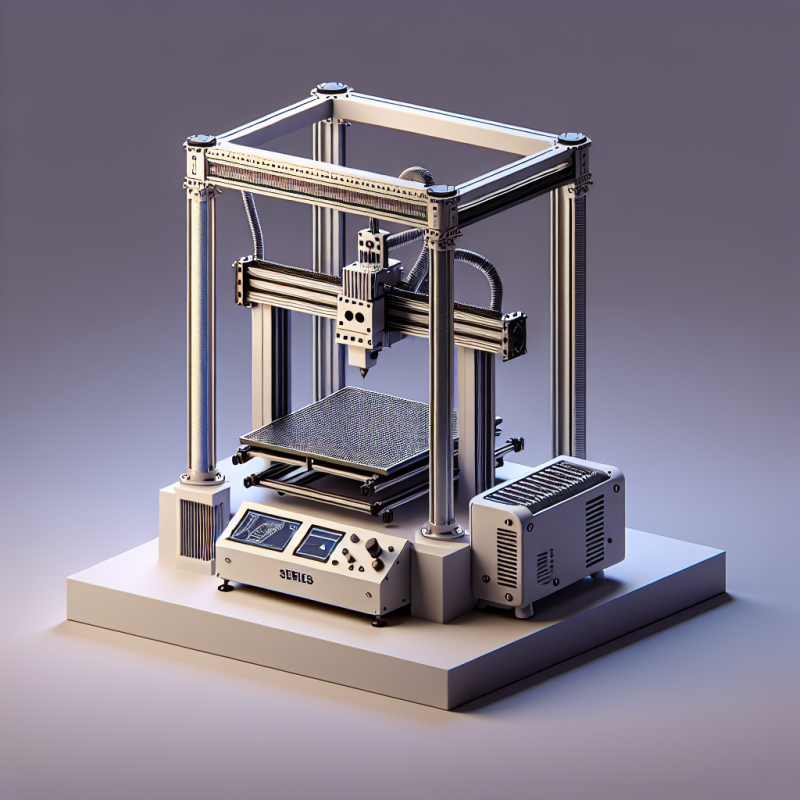

Machine Specifications and Features

When choosing a laser engrave knife laser engraving machine, several specifications and features are crucial to consider:

- Laser Power: Higher wattage lasers can cut thicker materials and engrave faster. Common powers range from 30W to 100W or more.

- Beam Quality: A focused, high-quality beam ensures precision and clean cuts.

- Workspace Size: Larger beds accommodate bigger workpieces. Measure your typical project dimensions to select an appropriate size.

- Software Compatibility: Machines should come with software that allows for easy design import, editing, and job setup. Compatibility with popular CAD/CAM software is beneficial.

- Control Systems: Advanced control systems offer better precision and may include features like autofocus and real-time adjustments.

Many laser engrave knives also feature:

- Air Assist: Blows air across the cutting area to prevent heat buildup and smoke accumulation.

- Red Dot Pointer: Helps in aligning the laser beam with the desired engraving or cutting path.

- Exhaust Systems: Ventilate the workspace to remove harmful particles and odors.

Material Compatibility

Laser engrave knives are compatible with a wide variety of materials, each requiring different settings for optimal results:

- Woods: Engraves beautifully, with different species offering varying contrasts and textures.

- Leathers: Suitable for branding, personalization, and detailed patterns.

- Acrylics: Can be cut and engraved, producing vibrant, translucent effects.

- Metals: Engraves well, though thicker metals may require higher power settings or additional preprocessing.

- Plastics: Versatile materials that can be cut or engraved with precision.

- Papers and Fabrics: Ideal for intricate designs and personalization.

Safety Considerations

Operating a laser engrave knife laser engraving machine safely involves several practices:

- Eye Protection: Always wear laser-safe glasses when operating the machine or viewing the laser beam.

- Ventilation: Ensure adequate ventilation to prevent inhalation of laser-generated fumes and particles.

- Fire Precautions: Keep a fire extinguisher nearby and have a clear escape route in case of fire.

- Machine Enclosures: Use enclosed machines to contain laser beams and sparks.

- Training: Operators should receive thorough training on machine operation and safety procedures.

Industry Best Practices

Adopting industry best practices can enhance the efficiency and longevity of your laser engrave knife laser engraving machine:

- Regular Maintenance: Clean lenses, mirrors, and nozzles regularly to maintain beam quality.

- Calibration: Periodically calibrate the machine to ensure precision.

- Material Preparation: Properly secure workpieces to prevent movement during engraving.

- Software Optimization: Use software features to optimize pathing, reduce processing time, and minimize material waste.

- Quality Control: Inspect finished products for quality and make adjustments as needed.

Cost-Benefit Analysis

Investing in a laser engrave knife laser engraving machine offers several benefits, though the initial cost can be significant:

- Precision and Versatility: High precision and the ability to handle a wide range of materials make laser engraving machines versatile and efficient.

- Scalability: Machines can grow with your business, accommodating larger projects and higher volumes.

- Cost Savings: Over time, laser engraving can reduce labor costs and waste compared to traditional methods.

- Brand Differentiation: Offering personalized, high-quality engravings can differentiate your products and attract customers.

While the upfront cost may seem high, considering the long-term benefits, including increased productivity and reduced operational costs, can justify the investment.

Maintenance Tips

Maintaining your laser engrave knife laser engraving machine is crucial for optimal performance and longevity:

- Lens Cleaning: Use lens paper and cleaning solution to remove dust and debris from lenses and mirrors.

- Air Filter Replacement: Regularly replace air filters to maintain clean air flow and prevent clogging.

- Lubrication: Keep moving parts well-lubricated to reduce wear and tear.

- Software Updates: Regularly update software to access new features and improvements.

- Inspect Cables: Check power and data cables for damage, ensuring secure connections.

Project Ideas and Tutorials

To get the most out of your laser engrave knife laser engraving machine, consider these project ideas and tutorials:

- Personalized Cutting Boards: Engrave names or monograms onto cutting boards for a unique, personalized touch.

- Custom Jewelry: Create personalized jewelry pieces, such as engraved bracelets or pendants.

- Acrylic Signs: Design and cut vibrant, translucent signs for business or home decor.

- Leather Goods: Brand leather goods, such as wallets, bags, or keychains, with unique designs.