Fiber Laser Cutter: Precision Engraving and Cutting Made Easy

Are you looking for a versatile tool that can handle both intricate engraving and precise cutting? Look no further than the . This innovative machine is designed to meet the needs of professionals and hobbyists alike, offering unmatched precision and versatility. Whether you’re working with wood, metal, plastic, or other materials, this device can help you achieve professional-grade results every time.

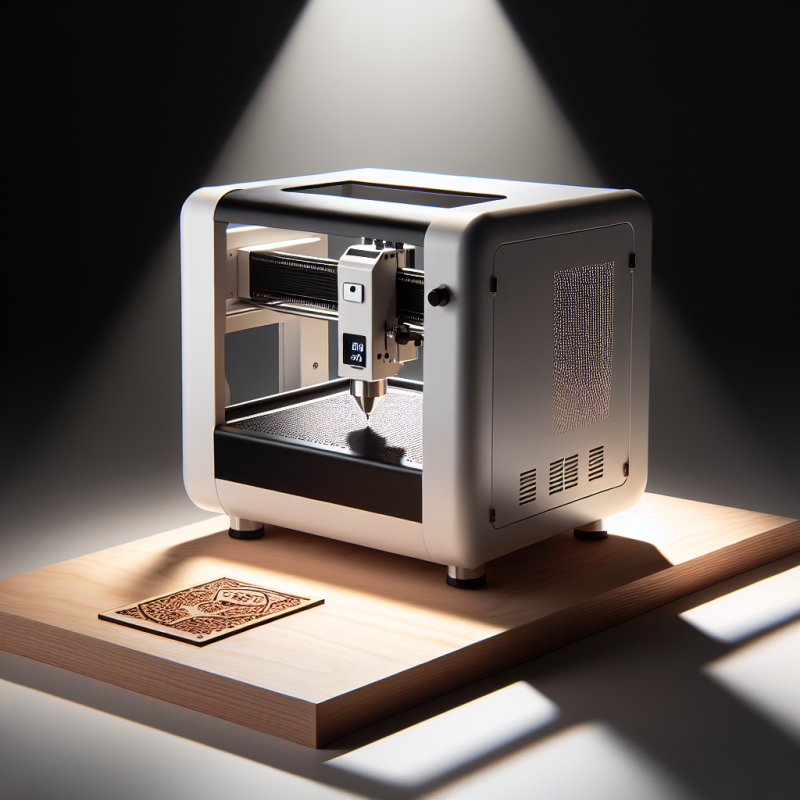

What Is a Fiber Laser Cutter?

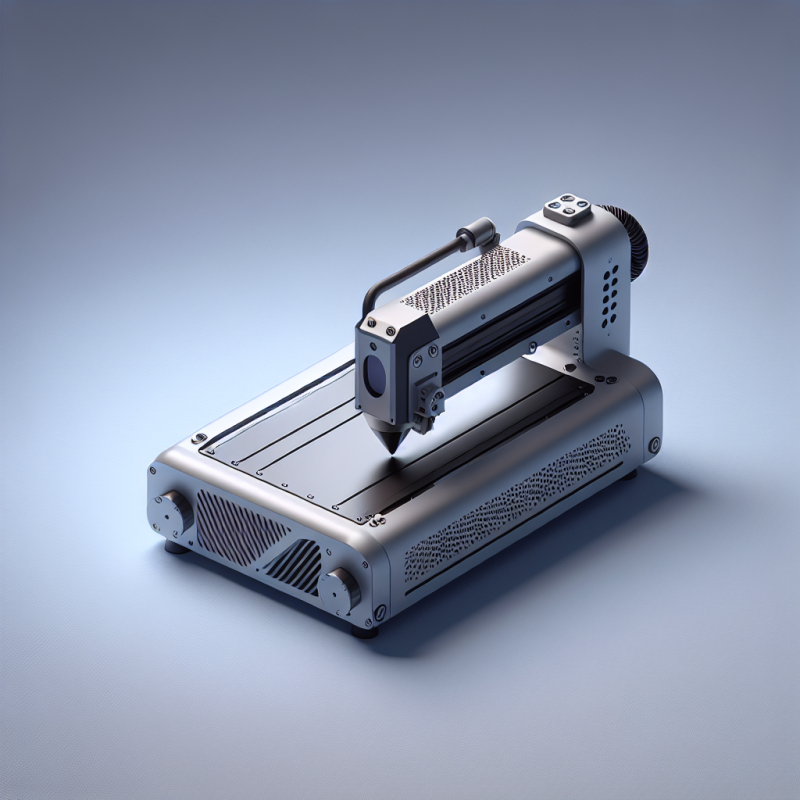

A fiber laser cutter is a cutting-edge tool that uses a high-powered laser to cut and engrave various materials. Unlike traditional tools, it operates with **extreme precision**, ensuring clean cuts and detailed engravings without damaging the material. The machine works by directing a focused beam of light at the material, which vaporizes or melts the surface to create the desired design.

The is particularly popular in industries such as jewelry making, sign-making, and custom fabrication. Its ability to work with a wide range of materials makes it an essential tool for creative professionals.

Applications of a Fiber Laser Cutter

The applications of a fiber laser cutter are virtually endless. Here are some of the most common uses:

- **Engraving**: Create detailed designs, patterns, and text on materials like wood, metal, and plastic.

- **Cutting**: Make precise cuts for creating intricate shapes or prototypes.

- **Marking**: Add permanent identification marks to products for branding or quality control.

- **Prototyping**: Quickly create prototypes for testing before full-scale production.

This machine is also ideal for small businesses and hobbyists who want to experiment with laser cutting without investing in expensive industrial equipment. With its compact design and user-friendly interface, it’s easy to get started even if you’re new to laser cutting.

Benefits of Using a Fiber Laser Cutter

There are several reasons why the is becoming a favorite among professionals:

- **Precision**: The machine’s laser beam ensures **unparalleled accuracy**, resulting in clean and sharp cuts.

- **Speed**: Compared to traditional cutting methods, the fiber laser cutter operates at **lightning-fast speeds**, saving you valuable time.

- **Versatility**: It works with a wide range of materials, making it suitable for diverse projects.

- **Cost-Effective**: Despite its advanced features, the machine is affordable and requires minimal maintenance.

If you’re wondering whether this tool is right for your needs, consider asking yourself: *Do I need a device that can handle both small-scale projects and large-scale production?* The fiber laser cutter is designed to meet all these requirements with ease.

Fiber Laser Cutter vs. Other Cutting Tools

When compared to traditional cutting tools, the offers several advantages:

- **No Physical Contact**: Unlike blade-based tools, the laser beam doesn’t physically touch the material, reducing the risk of damage.

- **Reduced Waste**: The precise cuts minimize material waste, making it ideal for cost-conscious projects.

- **Minimal Maintenance**: There are no blades to sharpen or replace, which means less downtime and lower maintenance costs.

If you’re in the market for a cutting tool that combines **precision**, **speed**, and **versatility**, the fiber laser cutter is hard to beat. It’s an investment that will pay off in the long run by improving your workflow and product quality.

Frequently Asked Questions

*Is the suitable for small businesses?*

Absolutely! Its compact size and affordability make it an excellent choice for small-scale operations. Plus, its ease of use means you don’t need extensive training to get started.

*What materials can I work with?*

The machine is compatible with a wide range of materials, including wood, metal, plastic, glass, and more. This versatility makes it suitable for various projects, from custom jewelry to signage.

*How easy is it to maintain?*

Maintenance is minimal compared to traditional tools. The lack of physical contact between the laser beam and the material means there’s no wear and tear on blades or cutting edges.

*Can I use it for large-scale production?*

Absolutely! While it’s perfect for small projects, the fiber laser cutter can also handle high-volume production with ease. Its speed and precision make it ideal for industrial applications.

Conclusion

If you’re looking for a reliable tool that can take your projects to the next level, the is worth considering. Its combination of precision, versatility, and affordability makes it an excellent choice for both professionals and hobbyists. Whether you’re creating intricate designs or cutting large-scale prototypes, this machine has the power to deliver outstanding results.

Don’t wait any longer—upgrade your workshop today with this innovative tool and unlock a world of creative possibilities!