Exploring the World of Laser Cutter Hobbyists

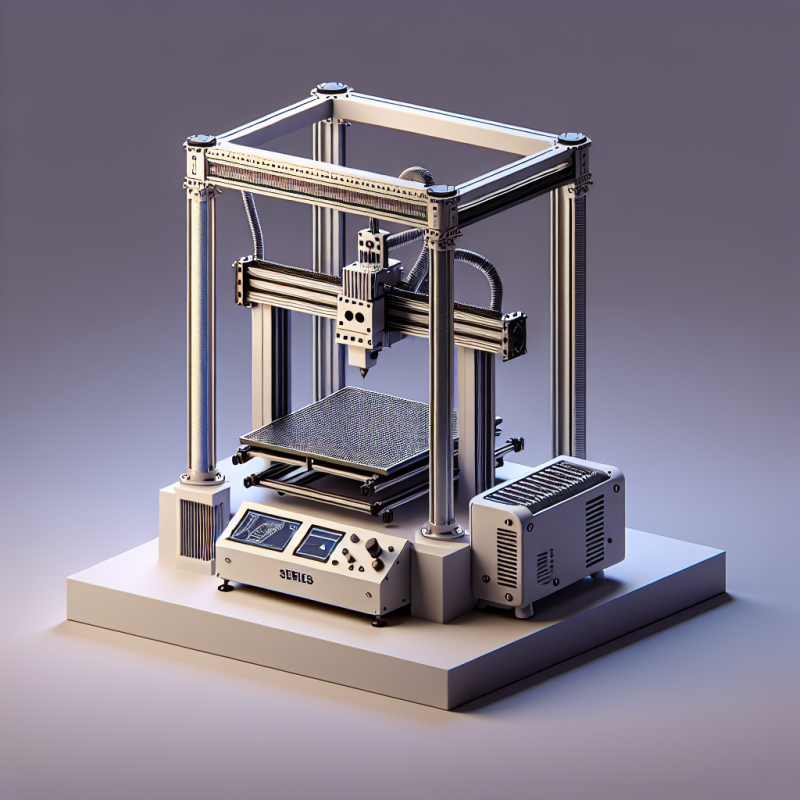

Laser cutting has become a fascinating hobby for many enthusiasts around the world. With its precision and versatility, this technology allows hobbyists to create intricate designs, cut materials with ease, and bring their creative ideas to life. For those looking to dive into this exciting field, the tools are a great starting point. Whether you’re a DIY enthusiast, an artist, or simply someone with a passion for innovation, this article will guide you through the world of laser cutting and how it can transform your creative projects.

##

The Rise of Laser Cutting as a Hobby

Laser cutting has evolved from being a tool used primarily in industrial settings to a popular hobby among crafters and makers. This shift is due, in part, to the availability of affordable and user-friendly laser cutter machines designed specifically for home use. The tools have made it easier than ever for individuals to experiment with this technology in the comfort of their own homes.

The appeal of laser cutting lies in its ability to create precise and detailed designs on a variety of materials, including wood, metal, plastic, and even fabric. This level of precision is hard to achieve with traditional tools, making it an attractive option for those looking to push the boundaries of their creativity. Whether you’re creating custom jewelry, decorative items, or functional objects, laser cutting offers endless possibilities.

If you’re new to laser cutting, you might be wondering: *What materials can I work with?* The answer is quite extensive! Most common materials are compatible with laser cutting, but it’s important to research the specific capabilities of your machine. For example, certain types of wood and plastic are ideal for laser cutting due to their smooth finish and ease of engraving.

##

Getting Started: Choosing the Right Equipment

One of the first steps in becoming a laser cutter hobbyist is selecting the right equipment. The market offers a wide range of laser cutter machines, from small, portable units to large industrial-grade systems. For beginners, it’s often best to start with a compact and user-friendly machine like the tool mentioned earlier.

When choosing your equipment, consider factors such as portability, budget, and the types of projects you plan to undertake. A portable laser cutter, for instance, is ideal if you want to work on-the-go or have limited workspace at home. On the other hand, larger machines are better suited for more complex projects that require greater precision and cutting power.

Another important consideration is the software compatibility of your laser cutter. Most modern machines come with user-friendly software that allows you to design and control your cuts with ease. If you’re already familiar with graphic design tools like Adobe Illustrator or CorelDRAW, you’ll likely find it easy to transition into laser cutting.

Before making a purchase, ask yourself: *What are my long-term goals?* This will help you decide whether to invest in a high-end machine now or start with a more affordable option and upgrade later. Many hobbyists begin with an entry-level model and gradually expand their setup as they gain experience.

##

Mastering the Basics: Understanding Laser Cutting

To become a skilled laser cutter hobbyist, it’s essential to understand the fundamentals of how this technology works. At its core, a laser cutter uses a focused beam of light to cut or engrave materials. The intensity and duration of the laser can be adjusted depending on the material being worked on.

Laser cutting offers several advantages over traditional methods:

- **Precision:** Laser beams are incredibly precise, allowing for intricate designs and clean cuts. This makes it ideal for creating delicate patterns or complex shapes.

- **Speed:** Compared to manual cutting, laser cutting is much faster, especially when dealing with repetitive tasks or large-scale projects.

- **Versatility:** As mentioned earlier, laser cutters can work with a wide variety of materials, making them suitable for numerous applications.

However, there are also some limitations to keep in mind. For example, certain materials may produce fumes when cut, so it’s important to use the machine in a well-ventilated area. Additionally, laser cutting can be more expensive than traditional methods for small-scale projects, though this cost is often offset by the precision and quality of the results.

If you’re just starting out, consider taking an online course or watching tutorials to learn the basics of laser cutting. Many forums and communities also exist where hobbyists share tips, tricks, and project ideas. Remember: practice makes perfect! Don’t be afraid to experiment with different materials and settings to find what works best for your projects.

##

Tips for Creating Stunning Laser-Cut Projects

Now that you’ve got the basics down, it’s time to start thinking about how to create stunning laser-cut projects. Here are a few tips to help you get started:

### 1. **Plan Your Design Carefully**

Before firing up your laser cutter, take the time to sketch out your design and consider how it will translate into a cut or engraved piece. Pay attention to details like spacing, alignment, and any potential overlaps that could cause issues during cutting.

### 2. **Start Small**

If you’re new to laser cutting, begin with simple projects like cutting letters or shapes in cardboard. This will allow you to get a feel for the machine and its settings without risking damage to expensive materials.

### 3. **Experiment with Materials**

Different materials react differently to laser cutting. For example, acrylic often produces a smooth, polished edge when cut, while wood can be engraved to create intricate designs. Don’t hesitate to experiment with various materials to see what effects you can achieve.

### 4. **Use Vector Graphics for Precision**

When designing your projects, use vector graphics rather than raster images. This ensures that your cuts will remain sharp and precise, even at high magnifications. Software like Adobe Illustrator or Inkscape is perfect for creating vector designs.

### 5. **Test Your Settings**

Before committing to a full project, test your laser cutter’s settings on a scrap piece of material. Adjust the power, speed, and focus as needed until you achieve the desired result.

By following these tips, you’ll be well on your way to creating professional-quality laser-cut projects. As you gain more experience, don’t hesitate to take on more complex designs or even combine laser cutting with other techniques like painting or 3D printing for added dimension.

##

Stay Inspired: Exploring Project Ideas

One of the best things about laser cutting is its versatility. Whether you’re interested in creating functional items, decorative pieces, or something purely artistic, there’s no shortage of project ideas to explore. Here are a few inspiration points to get your creative juices flowing:

### **Functional Items**

– Custom cutting boards with intricate designs.

– Laser-cut jewelry, such as pendants or earrings.

– Decorative wall hangings made from layered materials.

– Unique kitchen gadgets, like spice racks or serving trays.

### **Decorative Projects**

– 3D laser-cut models of buildings, vehicles, or animals.

– Intricate floral designs for wedding invitations or home decor.

– Geometric patterns cut into metal or wood for a modern look.

### **Artistic Creations**

– Abstract art pieces created by layering different materials.

– Engraved photo frames with personal touches.

– Laser-cut sculptures that play with light and shadow.

These ideas are just the tip of the iceberg! The beauty of laser cutting is that it allows you to combine your creativity with precision, resulting in one-of-a-kind pieces that reflect your unique style.

##

Maintaining Your Laser Cutter for Longevity

Like any tool, proper maintenance is key to ensuring your laser cutter stays in optimal condition. Regularly cleaning the machine and checking its components can help prevent issues down the line. Here are some maintenance tips:

### 1. **Clean the Machine After Each Use**

Dust and debris from cutting materials can accumulate on the machine’s surfaces, which may interfere with its performance over time. Wipe down the exterior and any accessible internal components after each use.

### 2. **Inspect the Focusing Lens**

The focusing lens is a critical component of your laser cutter. Over time, it may become dirty or scratched, which can affect the quality of your cuts. Clean the lens with a soft cloth and lens cleaner when necessary.

### 3. **Check for Alignment Issues**

Alignment problems can lead to uneven cuts or damaged materials. Periodically check the alignment of your laser cutter’s components and adjust as needed.

### 4. **Update Software Regularly**

If your laser cutter uses software, keep it updated to take advantage of new features and bug fixes. This ensures smooth operation and optimal performance.

By taking good care of your laser cutter, you can extend its lifespan and maintain the quality of your projects for years to come.

##

Conclusion

Laser cutting is a fascinating and versatile craft that allows you to create beautiful, precise designs with ease. Whether you’re a hobbyist or a professional, investing in a laser cutter opens up a world of possibilities for your creative projects. By starting small, experimenting with materials, and maintaining your equipment, you can unlock the full potential of this amazing technology.

If you’re just beginning your journey into laser cutting, remember that practice is key. Don’t be discouraged by minor setbacks or imperfections in your early work—each project is an opportunity to learn and grow. Over time, you’ll develop the skills and confidence needed to tackle even the most ambitious designs.

Happy creating!