Exploring the Mini Laser Engraving Machine: Precision in Your Hands

When it comes to precision and creativity, the mini laser engraving machine stands out as a revolutionary tool for both professionals and hobbyists. This compact yet powerful device has transformed how we approach tasks ranging from intricate artwork to industrial applications. In this article, we will delve into the features, benefits, and uses of the mini laser engraving machine, answering your most pressing questions along the way.

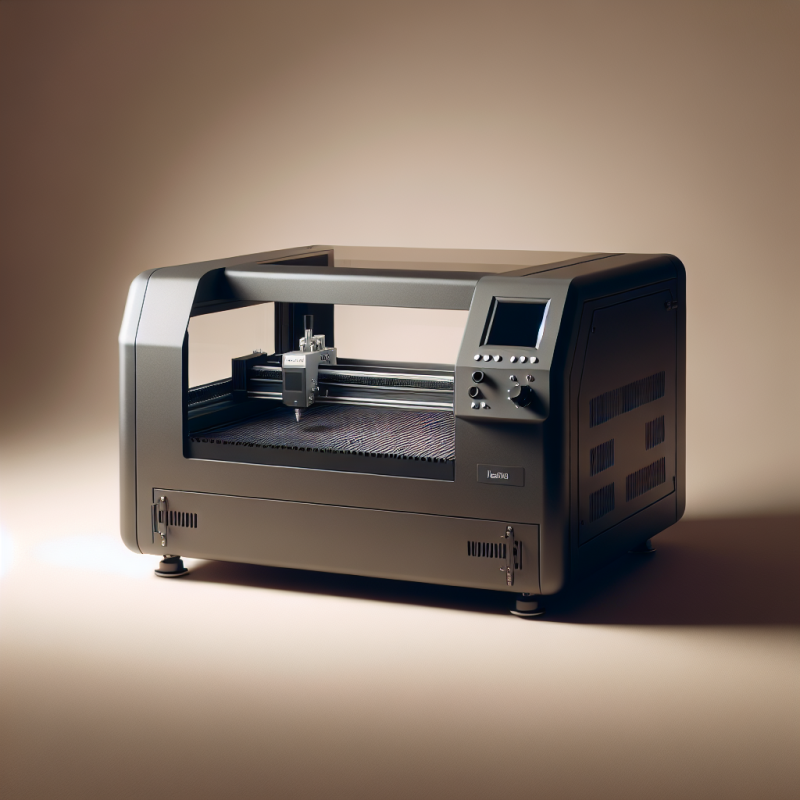

What is a Mini Laser Engraving Machine?

A mini laser engraving machine is a compact device designed for precision cutting and engraving. Unlike traditional methods, this machine uses a focused laser beam to etch or cut materials with extreme accuracy. Its portability and ease of use make it ideal for small-scale projects, while its high-quality output ensures professional-grade results.

One common question is, *how does a mini laser engraving machine differ from larger industrial models?* The answer lies in its size and versatility. While industrial lasers are often bulky and require specialized setups, the mini version offers flexibility without compromising on performance. This makes it perfect for home workshops, small businesses, or even educational settings.

How Does a Mini Laser Engraving Machine Work?

The operation of a mini laser engraving machine involves three main components: the laser source, the control system, and the work surface. The laser source emits a focused beam that heats and vaporizes material to create precise engravings or cuts. The control system allows users to input designs or patterns, which are then translated into movements of the laser head. Finally, the work surface holds the material in place during the engraving process.

*Is it difficult to learn how to use a mini laser engraving machine?* Fortunately, modern machines come with user-friendly interfaces and often include software that simplifies design input. Even those new to laser engraving can produce stunning results with minimal training. Additionally, many models offer adjustable settings for different materials, ensuring optimal performance regardless of the project.

Applications Across Industries

The versatility of a mini laser engraving machine makes it applicable across various industries. Let’s explore some key areas where this technology shines:

- Jewelry Making: Create custom engravings on metals and precious stones with unmatched precision.

- Fashion Design: Add intricate patterns to fabrics or leather goods for a unique touch.

- Electronic Components: Engrave circuit boards or small parts with detailed markings.

- Crafts and Art: Produce personalized gifts, signs, or decorative items using various materials like wood, acrylic, or glass.

- Medical Devices:,。

*Can this machine handle different types of materials?* Absolutely! Most mini laser engraving machines are compatible with a wide range of materials, including wood, metal, plastic, glass, and leather. This adaptability makes them an invaluable tool for diverse projects.

Benefits of Using a Mini Laser Engraving Machine

There are numerous reasons to consider investing in a mini laser engraving machine. Let’s highlight some of the key advantages:

- Precision and Accuracy: The focused laser beam ensures clean, precise cuts and engravings with minimal material waste.

- Speed and Efficiency: Compared to traditional methods, laser engraving is faster and requires less setup time.

- Versatility: Capable of handling various materials and project scales, this machine offers unparalleled flexibility.

- Cost-Effective: Despite its high-quality output, the mini version is more affordable than larger industrial models, making it accessible to a broader audience.

- User-Friendly: Modern designs prioritize ease of use, with intuitive controls and software that even beginners can master quickly.

*How does laser engraving compare to other methods in terms of cost?* While initial investment costs may vary, the long-term savings from reduced material waste and faster production times often justify the expense. Additionally, the ability to handle multiple projects efficiently further enhances its value.

Common Questions About Mini Laser Engraving Machines

Before purchasing a mini laser engraving machine, it’s natural to have questions. Here are some frequently asked ones:

- What maintenance is required?* Most machines require minimal upkeep, with periodic cleaning of the laser head and calibration to ensure optimal performance.

- How safe is a mini laser engraving machine?* As long as safety protocols are followed, such as using protective eyewear and ensuring proper ventilation, these machines are safe to operate.

- Can it be upgraded for more advanced projects?* Many models allow for upgrades, such as higher-powered lasers or additional software features, enabling users to scale their capabilities over time.

*Is a mini laser engraving machine suitable for large-scale production?* While it excels in small-scale projects, some models can handle moderate-sized tasks efficiently. For very large production runs, industrial-grade machines may still be more practical.

Choosing the Right Mini Laser Engraving Machine

Selecting the right mini laser engraving machine depends on your specific needs. Consider factors such as:

- Budget: Determine how much you’re willing to spend, keeping in mind the balance between quality and features.

- Type of Projects: Decide what materials and projects you’ll primarily work on to choose a machine with compatible specifications.

- User Experience: If you’re new to laser engraving, look for machines with user-friendly interfaces and comprehensive support resources.

*How do I know if a particular model is right for me?* Research reviews, compare features, and consider consulting with experts or other users who have experience with the machine. This will help you make an informed decision tailored to your needs.

The Future of Mini Laser Engraving Machines

As technology continues to advance, so does the potential of mini laser engraving machines. Innovations such as AI-driven design software and higher-powered lasers are making these devices even more versatile and efficient. Additionally, the growing emphasis on sustainability is leading to the development of eco-friendly materials compatible with laser engraving.

*How will these advancements impact users?* The future looks bright for hobbyists and professionals alike, offering new creative possibilities and improved productivity. As the technology becomes more accessible, we can expect to see even greater adoption across various industries.

Conclusion

A mini laser engraving machine is more than just a tool—it’s a gateway to precision, creativity, and efficiency. Whether you’re crafting intricate jewelry or producing custom designs for businesses, this device has the potential to elevate your work to new heights. By understanding its features, benefits, and applications, you can determine if it’s the right choice for your projects.

*Are you ready to take the plunge and invest in a mini laser engraving machine?* With careful consideration of your needs and budget, you can find a model that perfectly suits your requirements. Don’t hesitate to explore further and unlock the full potential of this amazing technology!