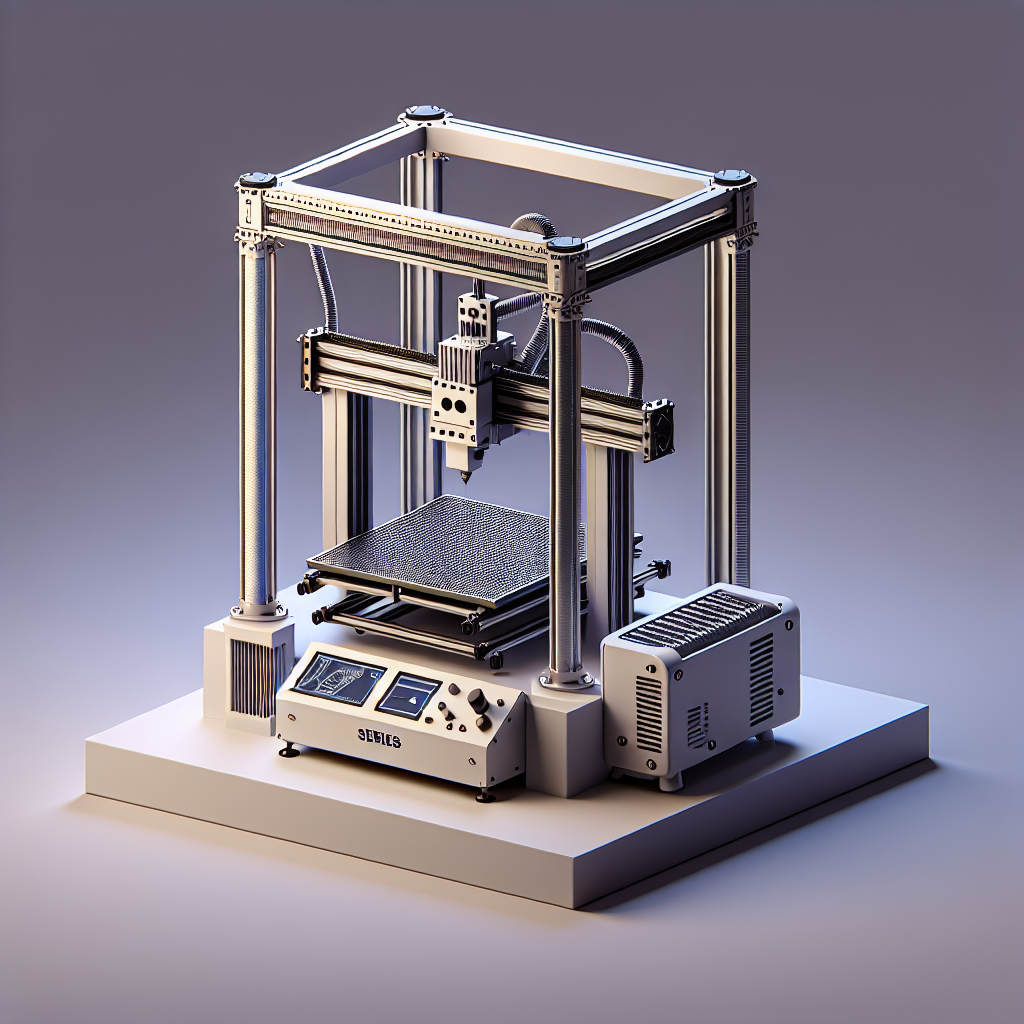

The Mini Laser Engraving Machine For Metal: A Comprehensive Guide

Are you looking for a precise and efficient tool to create detailed designs on metal surfaces? If so, the **mini laser engraving machine for metal** might be exactly what you need. This compact yet powerful device has become increasingly popular among hobbyists, craftsmen, and small-scale manufacturers who require high-quality engravings without the need for bulky equipment. In this article, we’ll explore everything you need to know about this innovative tool, including its features, applications, and how it can benefit your projects.

What is a Mini Laser Engraving Machine for Metal?

A **mini laser engraving machine for metal** is a compact device designed to etch intricate patterns, text, or images onto various types of metal surfaces. Unlike traditional engraving methods that use mechanical tools, this machine uses a focused laser beam to remove material layer by layer, creating precise and durable markings. The process is fast, clean, and suitable for both small-scale projects and industrial applications.

The **mini laser engraving machine** operates on the principle of laser ablation, where the laser beam vaporizes the metal surface at a microscopic level. This method ensures that even delicate designs can be etched with high precision. The machine is equipped with advanced software that allows users to input their designs and control the engraving process with ease.

Benefits of Using a Mini Laser Engraving Machine for Metal

There are numerous advantages to using a **mini laser engraving machine** for metal work. Let’s take a closer look at some of its key benefits:

- Precision and Accuracy: The laser beam ensures that every detail of your design is etched with pinpoint accuracy, making it ideal for complex patterns and text.

- Speed and Efficiency: Compared to traditional engraving methods, the laser process is much faster, allowing you to complete projects in less time.

- Versatility: The machine can handle a wide range of metal types, including steel, aluminum, stainless steel, and more. It’s also capable of engraving on non-metal surfaces like plastic and wood.

- Long-Lasting Results: Laser engravings are permanent and resistant to wear and tear, ensuring that your designs remain intact for years to come.

- Eco-Friendly: Unlike chemical etching methods, laser engraving produces no harmful byproducts, making it an environmentally friendly choice.

These benefits make the **mini laser engraving machine** a versatile and indispensable tool for anyone working with metal surfaces. Whether you’re creating custom jewelry, decorative items, or industrial components, this device can help you achieve professional-quality results every time.

How Does a Mini Laser Engraving Machine Work?

Understanding how the **mini laser engraving machine** works is essential for maximizing its potential. The process involves several key steps:

- Design Creation: First, you create your design using compatible software or import it from a file. The software allows you to scale, rotate, and adjust the design as needed.

- Laser Setup: Once the design is ready, you load it into the machine’s interface. You can adjust settings such as laser power, speed, and focus distance to ensure optimal engraving quality.

- Material Placement: The metal piece is secured in place on the machine’s worktable. It’s important to ensure that the material is properly aligned and clamped to prevent movement during the engraving process.

- Engraving Process: With a single click, the laser begins tracing the design onto the metal surface. The beam vaporizes the metal at a microscopic level, creating a precise and permanent mark.

- Post-Processing: After the engraving is complete, you may need to clean the area with a soft cloth or apply a protective coating to enhance the design’s visibility or durability.

This straightforward process ensures that even beginners can achieve professional-quality results with minimal effort. The machine’s user-friendly interface and advanced features make it accessible to everyone, regardless of their experience level.

Applications of a Mini Laser Engraving Machine for Metal

The **mini laser engraving machine** is a highly versatile tool that can be used in a wide range of applications. Here are some of the most common uses:

- Jewelry Making: Create intricate designs on rings, bracelets, necklaces, and other jewelry pieces.

- Custom Engraving: Add personalized text or logos to metal items like name tags, awards, and plaques.

- Metal Artwork: Produce decorative metal art, signs, and wall hangings with unique designs.

- Industrial Marking: Engrave serial numbers, part codes, and other identification marks on machinery components.

- Crafts and Hobby Projects: Use the machine for creative projects like etching metal bowls, frames, and decorative items.

These applications demonstrate the **mini laser engraving machine**’s versatility and its ability to meet the needs of various industries and hobbies. Whether you’re working on a small-scale project or an industrial application, this device can help you achieve outstanding results.

Choosing the Right Mini Laser Engraving Machine

If you’re considering purchasing a **mini laser engraving machine**, it’s important to choose one that meets your specific needs. Here are some factors to keep in mind:

- Laser Power: Higher power lasers are capable of engraving thicker materials and producing deeper marks. However, for delicate work, a lower-power laser may be more appropriate.

- Build Quality: Look for machines with durable construction and high-quality components to ensure longevity and reliability.

- User-Friendliness: Choose a machine with an intuitive interface and easy-to-use software for a seamless engraving experience.

- Compatibility: Ensure the machine supports the types of materials you’ll be working with, including different metals, plastics, and woods.

By considering these factors, you can select a **mini laser engraving machine** that provides optimal performance for your projects. For more information, check out our where we review some of the top models available today.

Tips for Getting Started with Laser Engraving

If you’re new to laser engraving, here are a few tips to help you get started:

- Start Small: Begin with simple designs and gradually work your way up to more complex patterns as you gain experience.

- Experiment with Settings: Don’t be afraid to adjust the laser power, speed, and focus distance to achieve the best results for your specific project.

- Use Protective Gear: Always wear safety goggles and gloves when operating the machine to protect yourself from any potential hazards.

- Practice on Scrap Material: Before engraving your final piece, test your design on scrap material to ensure it looks as expected.

By following these tips, you can make the most of your **mini laser engraving machine** and create stunning engravings with confidence.

Frequently Asked Questions

1. Can I use the mini laser engraving machine on all types of metal?

Yes, the **mini laser engraving machine** can be used on a variety of metals, including steel, aluminum, stainless steel, and more. However, it’s important to adjust the laser settings according to the type of metal you’re working with for optimal results.

2. Is laser engraving safe?

Laser engraving is generally safe when proper precautions are taken. Always wear safety goggles and ensure that the machine is operated in a well-ventilated area to avoid inhaling any fumes produced during the engraving process.

3. How long does it take to learn how to use the machine?

Most users can become proficient with the **mini laser engraving machine** within a few hours of practice. The user-friendly interface and intuitive software make it easy to start using the machine right away.

Conclusion

The **mini laser engraving machine for metal** is an invaluable tool for anyone looking to create precise and durable engravings on metal surfaces. Its compact design, versatility, and ease of use make it a popular choice among hobbyists, craftsmen, and industrial professionals alike. Whether you’re working on a small-scale project or an ambitious industrial application, this device can help you achieve outstanding results.

If you’re ready to take your engraving projects to the next level, consider purchasing a **mini laser engraving machine** today. With the right equipment and some practice, you’ll be able to create beautiful engravings that are sure to impress!