**The Ultimate Guide to Commercial Laser Engravers for Woodworking: A Comprehensive Overview**

Welcome to our in-depth exploration of commercial laser engravers, specifically tailored for woodworking enthusiasts and professionals. In this article, we’ll delve into the world of precision craftsmanship, uncovering how these machines are transforming industries and empowering creators. Whether you’re a seasoned artisan or just starting out, understanding the capabilities and benefits of a commercial laser engraver could be your next big step toward enhancing your projects. Let’s dive in!

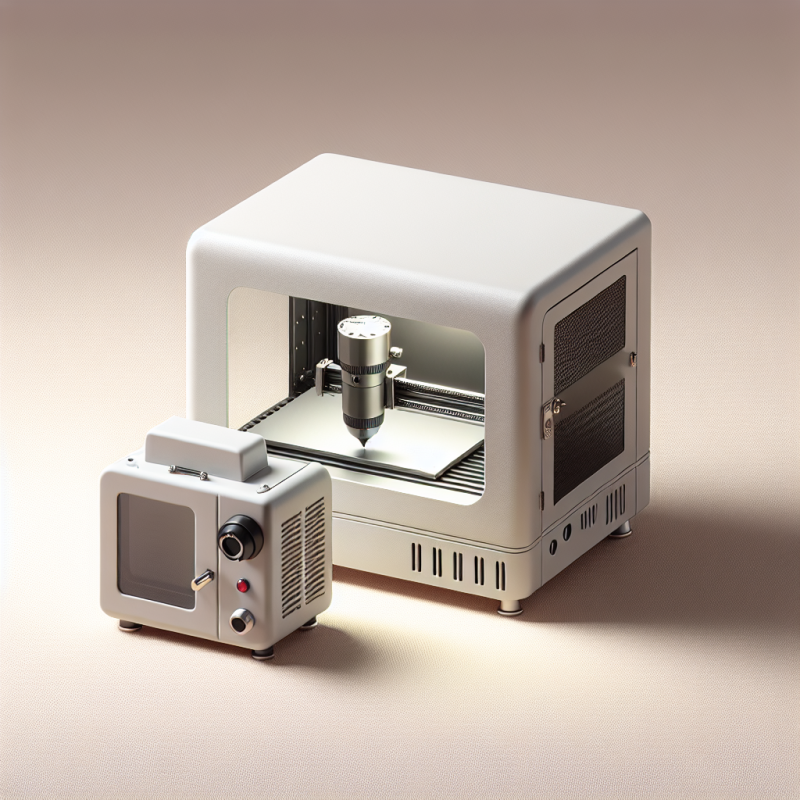

What is a Commercial Laser Engraver?

A commercial laser engraver is a precision tool designed to carve intricate designs, text, or patterns onto various materials, most notably wood. Unlike traditional methods that rely on mechanical cutting, laser engraving uses focused light beams to achieve unparalleled accuracy and detail. This technology has revolutionized industries ranging from furniture making to signage production, offering both efficiency and creativity.

These machines are highly versatile, capable of handling a wide range of materials beyond wood, including metal, leather, and plastics. However, their application in woodworking remains one of the most popular uses due to the natural beauty and versatility of wood as a medium. Whether you’re crafting custom frames, signage, or decorative items, a commercial laser engraver can elevate your work to new heights.

Why Choose a Commercial Laser Engraver?

The benefits of using a commercial laser engraver are manifold, making them an essential investment for any serious craftsman. Let’s explore some key reasons:

- Precision and Detail: Lasers can achieve levels of detail that are nearly impossible with traditional tools, allowing for intricate designs and fine text.

- Speed and Efficiency: Once programmed, laser engravers operate at high speeds, significantly reducing production time compared to manual methods.

- Versatility: Capable of working on multiple materials, these machines offer flexibility in design and application.

- Consistency: Every project can be replicated with identical precision, ensuring consistent quality across batches.

These advantages make commercial laser engravers a game-changer for businesses looking to enhance their output while maintaining high standards of quality.

Key Features to Look For in a Commercial Laser Engraver

When considering the purchase of a commercial laser engraver, it’s crucial to evaluate its features to ensure it meets your specific needs. Here are some key aspects to consider:

- Laser Power: Higher wattage lasers can handle thicker materials and faster engraving speeds.

- Bed Size: The work area should accommodate the size of your projects. Larger beds offer more flexibility but may require more space.

- Software Compatibility: User-friendly software with design tools or compatibility with popular CAD programs is essential for creating and modifying designs.

- Dust Extraction System: Ensures a clean working environment by efficiently removing dust generated during engraving.

Evaluating these features will help you choose the right machine that aligns with your craftsmanship goals and operational requirements.

Applications of Commercial Laser Engravers in Woodworking

The versatility of commercial laser engravers opens up a world of possibilities for woodworking projects. Here are some common applications:

- Custom Furniture: Add unique designs, initials, or decorative patterns to furniture pieces.

- Signage: Create professional-grade signs with detailed lettering and logos.

- Decorative Items: Craft intricate wood art, trays, coasters, and other decorative items.

- Framing: Engrave custom designs on picture frames or mirrors for a personalized touch.

These applications demonstrate the wide-ranging utility of laser engravers in transforming raw materials into works of art. Whether you’re producing one-of-a-kind pieces or, these machines offer the precision and speed needed to succeed.

Maintenance and Care for Your Commercial Laser Engraver

To ensure optimal performance and longevity, proper maintenance of your commercial laser engraver is essential. Here are some tips:

- Clean Regularly: Dust and debris can accumulate, so clean the machine and work area after each use.

- Calibrate Frequently: Regular calibration ensures accurate engraving and prevents errors in design execution.

- Inspect Components: Check mirrors, lenses, and other components for wear or damage to maintain efficiency.

- Use Genuine Parts: Invest in original parts to ensure compatibility and performance.

By following these maintenance practices, you can extend the lifespan of your laser engraver and maintain its high-performance standards over time.

Conclusion: Elevate Your Woodworking Projects with a Commercial Laser Engraver

In conclusion, a commercial laser engraver is more than just a tool; it’s an investment in precision, creativity, and efficiency. Whether you’re enhancing furniture, creating signage, or crafting decorative items, this technology opens up new avenues for your woodworking projects.

If you’re ready to take your craftsmanship to the next level, consider exploring the options available at [Your Website/Resource]. With a focus on quality and innovation, we provide the tools you need to bring your creative visions to life. Visit us today and discover how a commercial laser engraver can transform your woodworking business.

Thank you for joining us in this journey into the world of laser engraving. We look forward to helping you achieve new heights in your craftsmanship!