The Ultimate Guide to Laser Engravers and Cutters: Precision, Efficiency, and Creativity

Laser engravers and cutters have revolutionized industries ranging from woodworking to crafting, offering unparalleled precision and creativity. Whether you’re a hobbyist, a small business owner, or a professional artist, these machines provide the perfect tool for intricate designs and seamless cuts. In this article, we’ll explore the features, benefits, and applications of laser engravers and cutters, while addressing common questions to help you make an informed decision.

What is a Laser Engraver and Cutter?

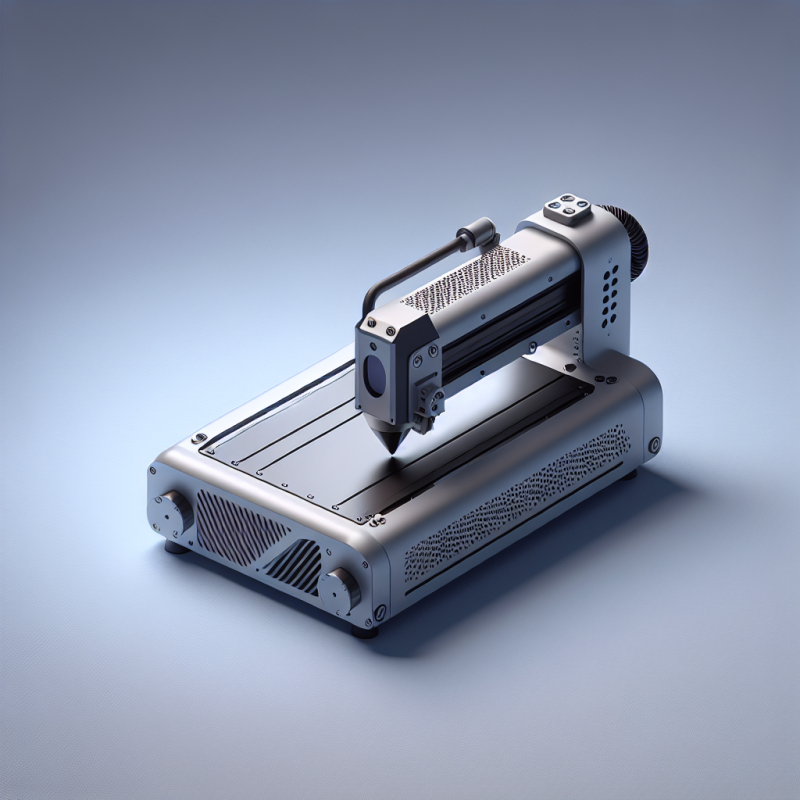

A **laser engraver and cutter** is a versatile machine that uses a focused laser beam to etch or cut materials with extreme precision. Unlike traditional tools, it allows for intricate designs and patterns that are difficult to achieve manually. The mini-laser engraver-cutter, such as the one available at , is compact yet powerful, making it ideal for small-scale projects.

Laser engraving involves creating detailed designs on materials like wood, metal, or plastic without cutting through them entirely. On the other hand, laser cutting uses a stronger beam to slice through materials cleanly. This dual functionality makes these machines indispensable for a wide range of applications.

Applications of Laser Engravers and Cutters

Laser engravers and cutters are used in various industries due to their versatility. Here are some common applications:

- Woodworking: Create custom furniture, decorative items, or signage with intricate designs.

- Jewelry Making: Engrave delicate patterns on metal or cutout shapes for unique pieces.

- Crafts: Design personalized gifts, such as engraved wooden boxes or decorative tiles.

- Signage and Advertising: Produce high-quality signs with sharp text and logos.

- Prototyping: Quickly create models for testing before full-scale production.

These machines are also perfect for DIY projects, allowing hobbyists to bring their creative ideas to life. For example, you can use a mini-laser engraver-cutter to etch your name on a wooden plaque or cut out precise shapes for.

Benefits of Using Laser Engravers and Cutters

The advantages of using laser engravers and cutters are numerous:

- Precision: The laser beam ensures accurate cuts and engravings, even for complex designs.

- Speed: Compared to traditional methods, laser cutting and engraving are faster, saving time and increasing productivity.

- Versatility: Suitable for a wide range of materials, including wood, metal, plastic, and glass.

- Ease of Use: Many models, like the mini-laser engraver-cutter, are user-friendly with intuitive controls.

- Durability: Laser machines are built to last, providing long-term value for both personal and professional use.

These benefits make laser engravers and cutters a valuable investment for anyone looking to enhance their crafting or production capabilities. For instance, if you’re running a small business, having a reliable machine can help you meet customer demands efficiently while maintaining high-quality standards.

How to Choose the Right Laser Engraver and Cutter

Selecting the right laser engraver and cutter depends on your specific needs. Consider the following factors:

- Budget: Determine how much you’re willing to spend, as prices vary based on features and power.

- Material Compatibility: Ensure the machine can handle the materials you’ll be working with (e.g., wood, metal, or plastic).

- Power Output: Higher wattage lasers are better for thicker materials but may require more advanced safety precautions.

- User-Friendliness: Look for machines with easy-to-use interfaces and software compatibility.

If you’re unsure which model to choose, consider starting with a compact option like the mini-laser engraver-cutter. It’s perfect for small projects and provides a good balance of power and affordability. Visit to explore your options.

Maintenance Tips for Laser Engravers and Cutters

To ensure optimal performance and longevity, proper maintenance is essential:

- Cleanliness: Regularly clean the machine to remove dust and debris that can interfere with operations.

- Lens Care: Keep the laser lens free from scratches or smudges, as they can affect beam focus.

- Firmware Updates: Stay updated with software patches to improve functionality and fix potential issues.

By following these tips, you’ll maximize the lifespan of your machine while maintaining its precision and efficiency. For example, cleaning after each use can prevent dust buildup, ensuring consistent performance over time.

Frequently Asked Questions (FAQs)

1. Can I engrave metal with a mini-laser engraver-cutter?

Yes, many models are capable of engraving metal, though the quality may vary depending on the laser’s power and the material thickness.

2. Is it safe to use a laser engraver at home?

When used with proper safety precautions (e.g., protective eyewear and adequate ventilation), laser engravers are safe for home use. Always follow the manufacturer’s guidelines to minimize risks.

3. Can I upgrade my machine in the future?

Some models allow for upgrades, such as higher wattage lasers or additional features, depending on the manufacturer’s offerings.

Conclusion

Laser engravers and cutters are powerful tools that offer precision, versatility, and efficiency for a wide range of applications. Whether you’re a hobbyist, artist, or business owner, investing in one of these machines can elevate your projects to new heights. With the mini-laser engraver-cutter available at , you’ll have a compact yet capable machine at your disposal.

Remember to consider your specific needs when choosing a model, and always prioritize safety during operation. By doing so, you’ll unlock the full potential of laser engraving and cutting, bringing your creative visions to life with ease and precision.