The Art and Science of Laser Engraving for Wood: A Comprehensive Guide

Laser engraving for wood has become one of the most popular methods for creating intricate, durable, and visually stunning designs on wooden surfaces. This innovative technique combines precision with creativity, allowing artists, craftsmen, and hobbyists to bring their ideas to life in ways that traditional carving simply cannot match. Whether you’re designing furniture, creating custom gifts, or restoring antique woodwork, laser engraving for wood offers unparalleled versatility and quality.

What is Laser Engraving?

Laser engraving is a process that uses a focused beam of light to etch or cut designs into materials. Unlike traditional engraving methods, which rely on mechanical cutting tools, laser engraving uses heat to remove material, leaving behind precise and intricate patterns. This method is particularly effective for wood because it allows for **extremely detailed work** without damaging the surrounding areas.

When applied to wood, laser engraving can create both **shallow engravings** (perfect for text or simple designs) and **deep cuts** (ideal for creating 3D effects or complex patterns). The process is not only faster than manual carving but also produces consistently high-quality results. This makes it a favorite among professionals who value precision and efficiency.

The Process of Laser Engraving for Wood

To understand how laser engraving works, let’s break down the process into its essential steps:

- Design Creation: The first step is to create a digital design using specialized software. This design will dictate the exact pattern that will be engraved onto the wood.

- Material Preparation: The wood must be properly prepared before engraving. This includes sanding the surface to ensure smoothness and applying any necessary protective coatings.

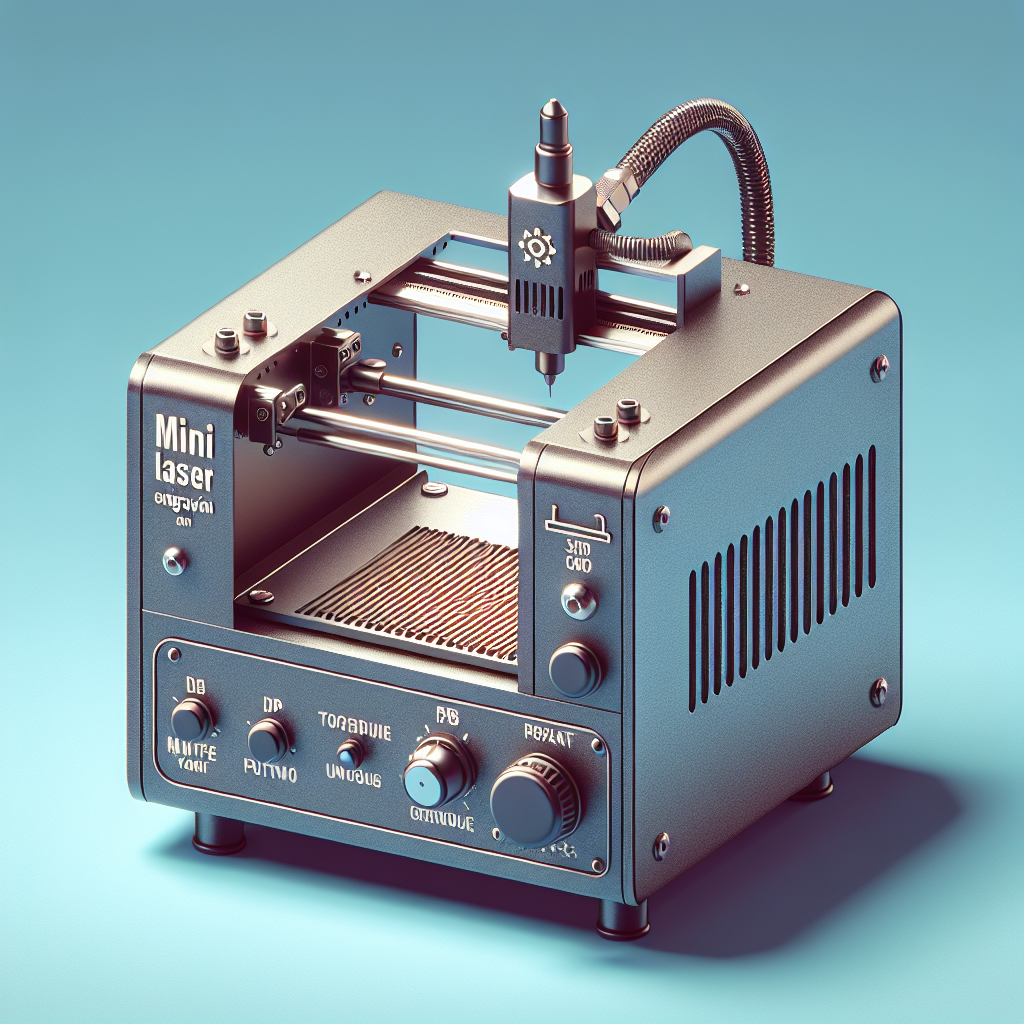

- Laser Setup: The laser machine is calibrated based on the design specifications, including depth, speed, and power settings.

- Engraving Execution: The laser beam traces the design onto the wood, removing material to create the desired pattern. This step is fully automated and requires minimal human intervention.

- Post-Processing: After engraving, the wood may undergo additional steps such as staining or sealing to enhance its appearance and durability.

This process ensures that every piece of wood is transformed into a unique, high-quality product. The use of advanced laser technology guarantees **consistent results**, even for large-scale projects.

Benefits of Laser Engraving for Wood

There are numerous advantages to using laser engraving for wood over traditional methods:

- Precision and Detail: Lasers can create intricate designs with **unparalleled precision**, making them ideal for complex patterns or fine text.

- Durability: Laser engravings are resistant to wear and tear, ensuring that your design remains vibrant for years to come.

- Customization: With digital design capabilities, you can create completely unique patterns tailored to your specific needs.

- Versatility: Laser engraving works on a wide variety of wood types, from softwoods like pine to hardwoods like oak or walnut.

- Eco-Friendly: The process is clean and produces minimal waste, making it an environmentally responsible choice.

These benefits make laser engraving a **versatile and sustainable** option for a wide range of applications. Whether you’re working on a small project or a large-scale production run, this method offers unmatched flexibility and quality.

Applications of Laser Engraving for Wood

Laser engraving for wood has endless possibilities. Here are some of the most common applications:

- Personalized Items: From custom name tags to engraved jewelry boxes, laser engraving allows you to create **one-of-a-kind gifts** that are sure to impress.

- Furniture Design: Woodworkers can use this technique to add decorative elements or intricate patterns to tables, chairs, and other furniture pieces.

- Home Decor: Engraved wood panels, wall art, and custom flooring are just a few examples of how laser engraving can enhance your home’s aesthetic appeal.

- Signage: Custom signs for businesses or homes often benefit from the precision and durability of laser engraving.

- Restoration: Restoring antique woodwork or repairing damaged surfaces is another area where this technology shines.

The possibilities are truly limitless. With the right design and equipment, you can transform any piece of wood into a stunning work of art.

Considerations for Laser Engraving on Wood

While laser engraving offers many advantages, there are several factors to consider when working with this method:

- Type of Wood: Different wood species have varying densities and textures, which can affect the engraving process. Hardwoods like oak or maple are generally more durable but may require higher laser settings.

- Design Complexity: More intricate designs will take longer to complete and may require more advanced software for accurate rendering.

- Post-Engraving Treatment: Some projects may benefit from additional treatments, such as staining or sealing, to enhance their appearance and longevity.

By carefully considering these factors, you can ensure that your laser engraving project achieves the desired results while minimizing costs and time.

Frequently Asked Questions

- Can laser engraving be used on all types of wood? While most woods are suitable for laser engraving, very dense or oily woods may require special handling. Always test your material before starting a large project.

- Is laser engraving safe? Yes, but proper safety precautions must be taken to protect against laser exposure and fumes generated during the process.

- How long does it take to learn laser engraving? Basic operations can be learned quickly with training, but mastering advanced techniques may require more time and practice.

If you’re new to laser engraving, consider starting with simple projects and gradually working your way up to more complex designs. This approach will help you build confidence and skills while minimizing the risk of errors.

The Future of Laser Engraving for Wood

As technology continues to advance, laser engraving is becoming increasingly accessible and affordable. Innovations in software and hardware are making it easier than ever to create stunning designs without needing extensive technical expertise.

One exciting development in the field is the use of **AI-driven design tools** that can automatically generate patterns based on user preferences. This technology not only saves time but also allows for more creative and unique designs.

In addition, advancements in laser efficiency are reducing energy consumption and lowering operational costs. These improvements make laser engraving an even more attractive option for both small-scale hobbyists and large industrial operations.

Conclusion

Laser engraving for wood is a powerful tool that combines precision, versatility, and creativity. Whether you’re looking to create custom gifts, design furniture, or restore antique pieces, this method offers unmatched potential. By understanding the process, benefits, and applications of laser engraving, you can unlock new possibilities for your woodworking projects.

If you’re ready to take your woodwork to the next level, consider exploring the world of laser engraving. With the right equipment and knowledge, you’ll be able to produce truly extraordinary results that will leave a lasting impression.