The Ultimate Guide to Laser Wood Cutter Machines

Are you looking for a versatile tool that can transform your woodworking projects into precision art? If so, then you’ve come to the right place. This article will explore everything you need to know about **laser wood cutter machines**, including their features, benefits, and how they can revolutionize your crafting or manufacturing processes.

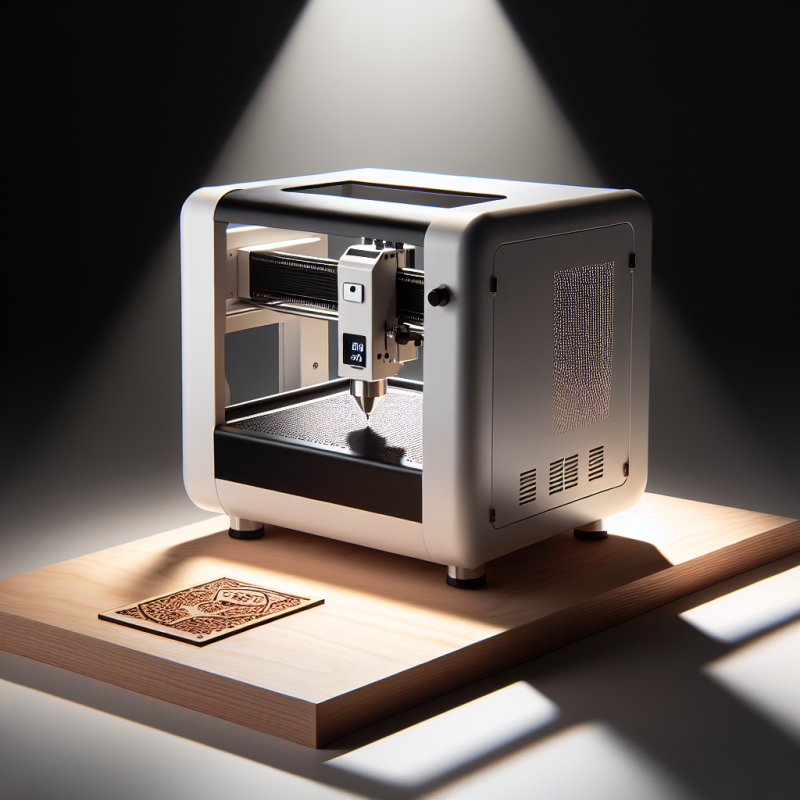

What is a Laser Wood Cutter Machine?

A **laser wood cutter machine** is an advanced tool designed to cut, engrave, and etch various materials with extreme precision. Unlike traditional woodworking tools, this machine uses a focused laser beam to create intricate designs, patterns, and shapes on wood, metal, plastic, and more. The result? Clean, precise cuts that are impossible to achieve manually.

These machines are ideal for hobbyists, artists, and small-scale manufacturers who want to create custom products without the need for expensive industrial equipment. Whether you’re making furniture, decorative items, or signage, a **laser wood cutter machine** can help you bring your ideas to life with ease.

Why Choose a Laser Wood Cutter Machine?

If you’re wondering why you should invest in a **laser wood cutter machine**, here are some compelling reasons:

- Precision and Accuracy: The laser beam ensures that every cut, engraving, or etching is perfectly executed, eliminating the guesswork involved with traditional tools.

- Versatility: You can work with a wide range of materials, including wood, metal, plastic, leather, and more.

- Speed: Laser cutting is significantly faster than manual methods, allowing you to complete projects in less time.

- Customization: You can create unique designs using computer software, making it easy to customize each project.

These benefits make a **laser wood cutter machine** an excellent investment for anyone looking to enhance their crafting or manufacturing capabilities.

Applications of Laser Wood Cutter Machines

The applications of a **laser wood cutter machine** are vast and varied. Here are some popular uses:

- Furniture Making: Create custom-cut pieces for tables, chairs, and other furniture items.

- Decorative Items: Design personalized signs, wall art, and home decor with intricate details.

- Crafts: Make unique gifts like laser-engraved wooden boxes, jewelry, and ornaments.

- Signage: Produce high-quality signs for businesses, homes, or events.

If you’re asking yourself, “What can I do with a laser wood cutter machine?” the answer is simple: Almost anything your imagination can conceive!

How Does a Laser Wood Cutter Machine Work?

To understand how a **laser wood cutter machine** operates, let’s break it down into its basic components:

- Laser Source: The laser generates a high-energy beam that heats and vaporizes the material being cut.

- Focusing Lens: This lens concentrates the laser beam onto the workpiece, ensuring precise cutting.

- Control System: Most machines are controlled by computer software that directs the laser’s movements based on your design.

The process begins with designing your project using specialized software. Once the design is ready, it’s sent to the machine, which then uses the laser beam to cut or engrave the material exactly as specified. The result is a clean, professional finish that requires minimal post-processing.

Key Features to Look for in a Laser Wood Cutter Machine

When shopping for a **laser wood cutter machine**, there are several features you should consider:

- Laser Power: Higher power lasers are capable of cutting thicker materials, making them ideal for industrial use.

- Cutting Speed: Faster machines can complete projects in less time, which is essential for commercial applications.

- Material Compatibility: Ensure the machine can handle the types of materials you plan to work with.

- User-Friendly Interface: Look for machines with intuitive software and controls to make operation easier.

If you’re a hobbyist or small-scale manufacturer, you don’t need the most powerful machine available. Instead, focus on finding one that offers a good balance of performance, versatility, and ease of use.

Maintenance and Safety Tips

Like any precision tool, a **laser wood cutter machine** requires proper maintenance to ensure optimal performance. Here are some tips:

- Clean Regularly: Remove dust and debris after each use to keep the machine running smoothly.

- Check Components: Inspect the laser lens, focusing optics, and other components for wear or damage.

- Follow Safety Guidelines: Always wear protective eyewear and ensure proper ventilation when operating the machine.

Safety should always be a top priority when working with lasers. By following these guidelines, you can enjoy years of reliable service from your **laser wood cutter machine**.

Frequently Asked Questions

1. Can I use a laser wood cutter machine for metal cutting?

Yes! Many **laser wood cutter machines** are capable of cutting and engraving metals, such as stainless steel and aluminum. However, ensure the machine’s specifications match your material requirements.

2. Is it easy to learn how to use a laser wood cutter machine?

With proper training and user-friendly software, even beginners can master the basics of operating a **laser wood cutter machine** in no time.

3. What’s the best material for laser cutting?

Wood is one of the most popular materials due to its compatibility with lasers. However, acrylics and plastics are also excellent choices for creating decorative items.

Conclusion

If you’re ready to take your woodworking or crafting projects to the next level, a **laser wood cutter machine** is an invaluable tool to consider. Its precision, versatility, and speed make it a must-have for anyone looking to create high-quality, custom designs. Why wait? Start exploring the world of laser cutting today!

To learn more or purchase a , visit our website and discover how this tool can transform your projects into works of art.